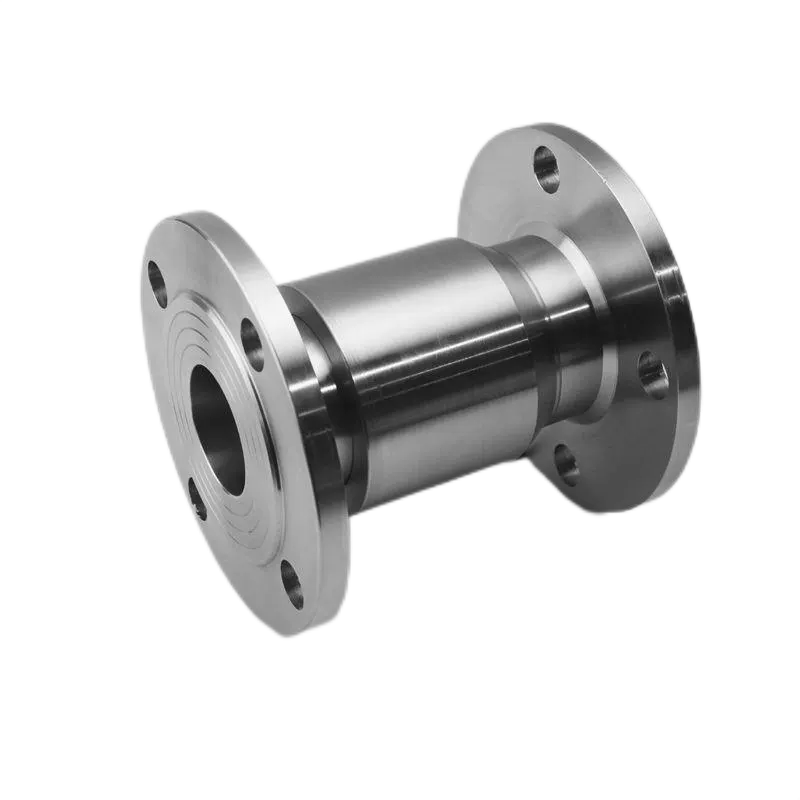

ball universal joint

A ball universal joint is a sophisticated mechanical component that enables flexible motion transmission between two shafts positioned at varying angles. This versatile mechanism consists of a ball-shaped member housed within a socket, allowing for smooth rotational movement in multiple directions. The joint's design incorporates precision-engineered bearing surfaces that maintain constant velocity during operation, ensuring efficient power transfer across different angular positions. The ball universal joint excels in applications requiring reliable performance under challenging conditions, offering superior flexibility and durability compared to traditional joint designs. Its unique construction allows for angular misalignment compensation while maintaining torque transmission efficiency, making it ideal for various industrial and automotive applications. The joint's ability to operate at different angles while minimizing vibration and wear has made it an essential component in modern machinery, from steering systems to industrial equipment. Manufacturing processes incorporate high-grade materials and precise engineering tolerances to ensure optimal performance and longevity. The ball universal joint's capability to handle both axial and angular movements while maintaining smooth operation has established it as a crucial component in mechanical power transmission systems.