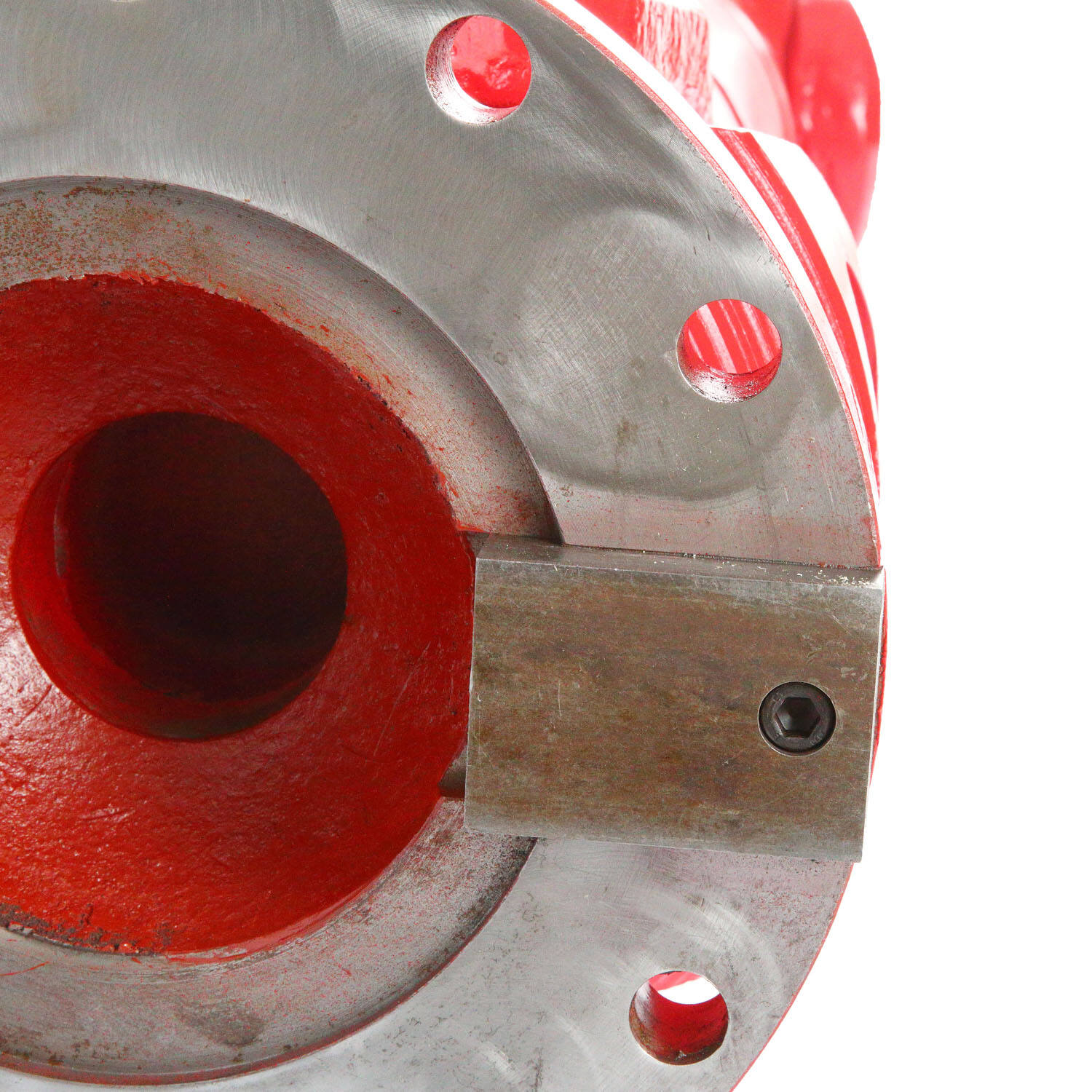

cardan shaft coupling

A cardan shaft coupling represents a crucial mechanical component designed to transmit rotational power between two shafts that may be misaligned. This sophisticated device consists of two or more universal joints connected by an intermediate shaft, allowing for angular, parallel, and axial misalignment compensation. The coupling's primary function involves maintaining consistent power transmission while accommodating various types of shaft misalignments that commonly occur in industrial machinery. The design incorporates precision-engineered universal joints, which utilize cross-shaped components surrounded by needle bearings to ensure smooth operation and minimal friction. These couplings are extensively used in automotive drivetrains, industrial machinery, and heavy equipment where power must be transmitted between non-aligned shafts. The cardan shaft coupling's ability to handle significant torque loads while maintaining operational efficiency makes it indispensable in numerous applications. Modern variants often feature advanced materials and specialized lubricants to enhance durability and reduce maintenance requirements, ensuring reliable performance even under demanding conditions.