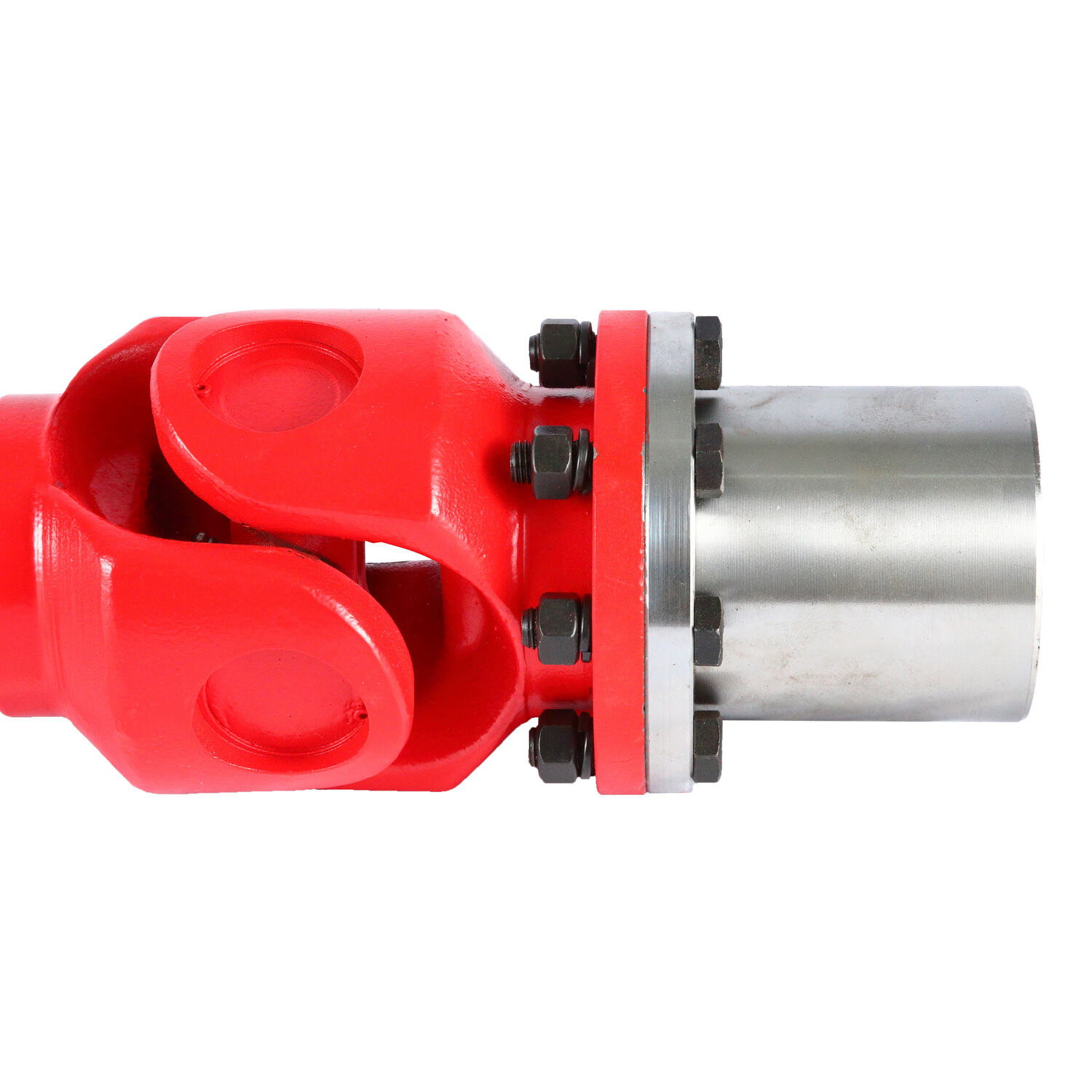

china cross joint

The China Cross Joint represents a crucial mechanical component designed for transmitting rotational motion and torque between intersecting shafts, typically positioned at right angles. This sophisticated joint mechanism features precision-engineered components, including a central cross-shaped element with four bearing caps that enable smooth rotation in multiple directions. Manufactured to strict quality standards, these joints incorporate hardened steel construction with specialized heat treatment processes to ensure durability and longevity. The design accommodates various shaft sizes and can handle significant torque loads while maintaining operational stability. Modern China Cross Joints often feature enhanced sealing systems to prevent lubricant leakage and protect against environmental contaminants, making them suitable for diverse industrial applications. These joints are extensively used in automotive driveshafts, industrial machinery, agricultural equipment, and construction vehicles. The component's design allows for angular misalignment between connected shafts while maintaining consistent power transmission efficiency. Advanced manufacturing techniques ensure precise balancing and minimal vibration during operation, contributing to reduced wear and extended service life.