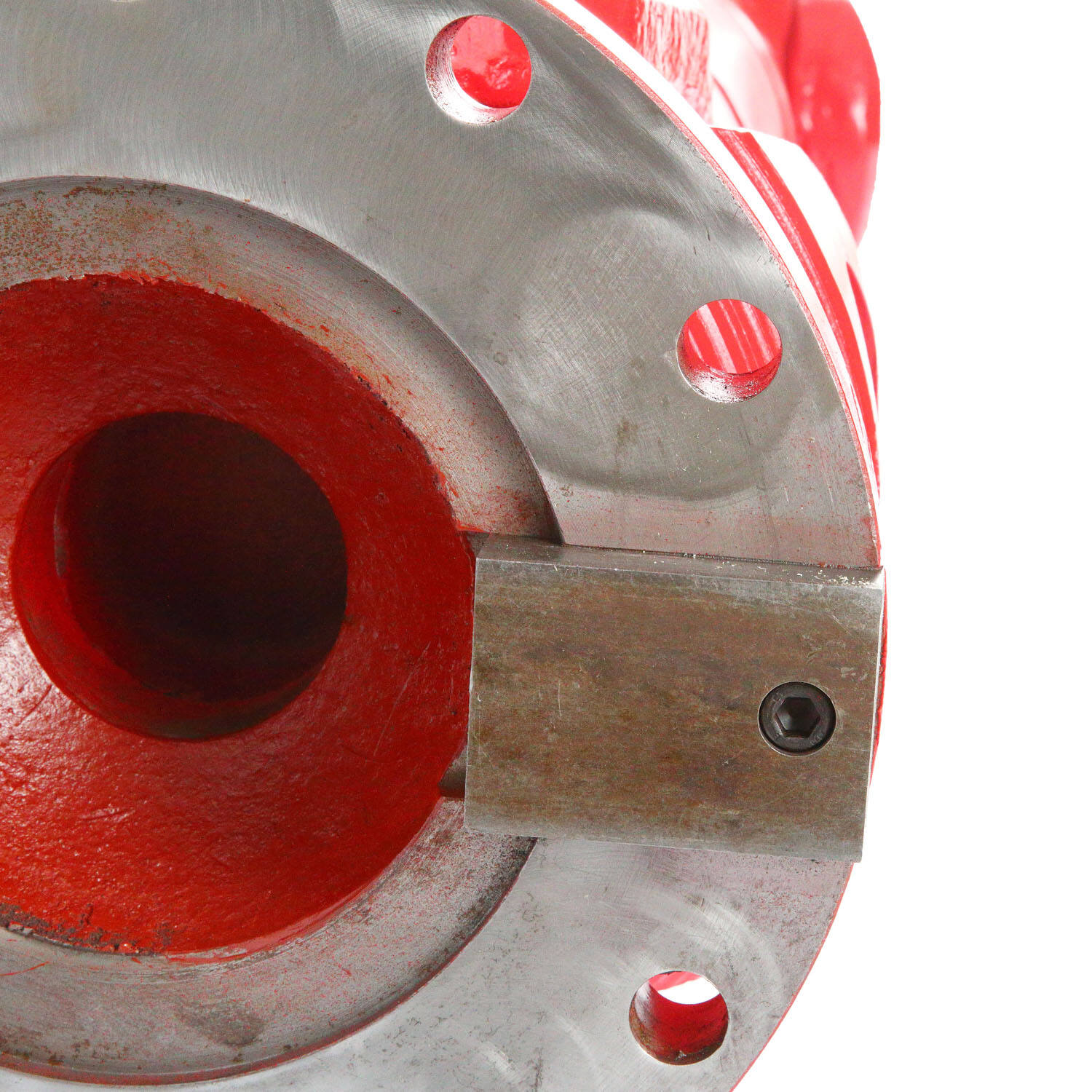

flexible spring coupling

A flexible spring coupling is an essential mechanical component designed to connect and transmit torque between two shafts while accommodating misalignment and absorbing shock loads. This innovative coupling utilizes a series of precision-engineered springs arranged in a specific pattern to create a flexible connection that maintains optimal power transmission efficiency. The design incorporates high-strength steel springs that are carefully calibrated to provide the perfect balance between flexibility and stability. These couplings excel in applications where shaft misalignment is common, such as in industrial machinery, pumps, compressors, and various power transmission systems. The spring elements can effectively handle angular, parallel, and axial misalignments while maintaining smooth operation and reducing vibration. The flexible spring coupling's unique construction allows it to operate without lubrication, making it a low-maintenance solution for various industrial applications. Its design also incorporates safety features that protect connected equipment from sudden shock loads and torque spikes, effectively extending the lifespan of the entire drive system. The coupling's versatility makes it suitable for both high-speed and low-speed applications, with different spring configurations available to match specific torque requirements and operating conditions.