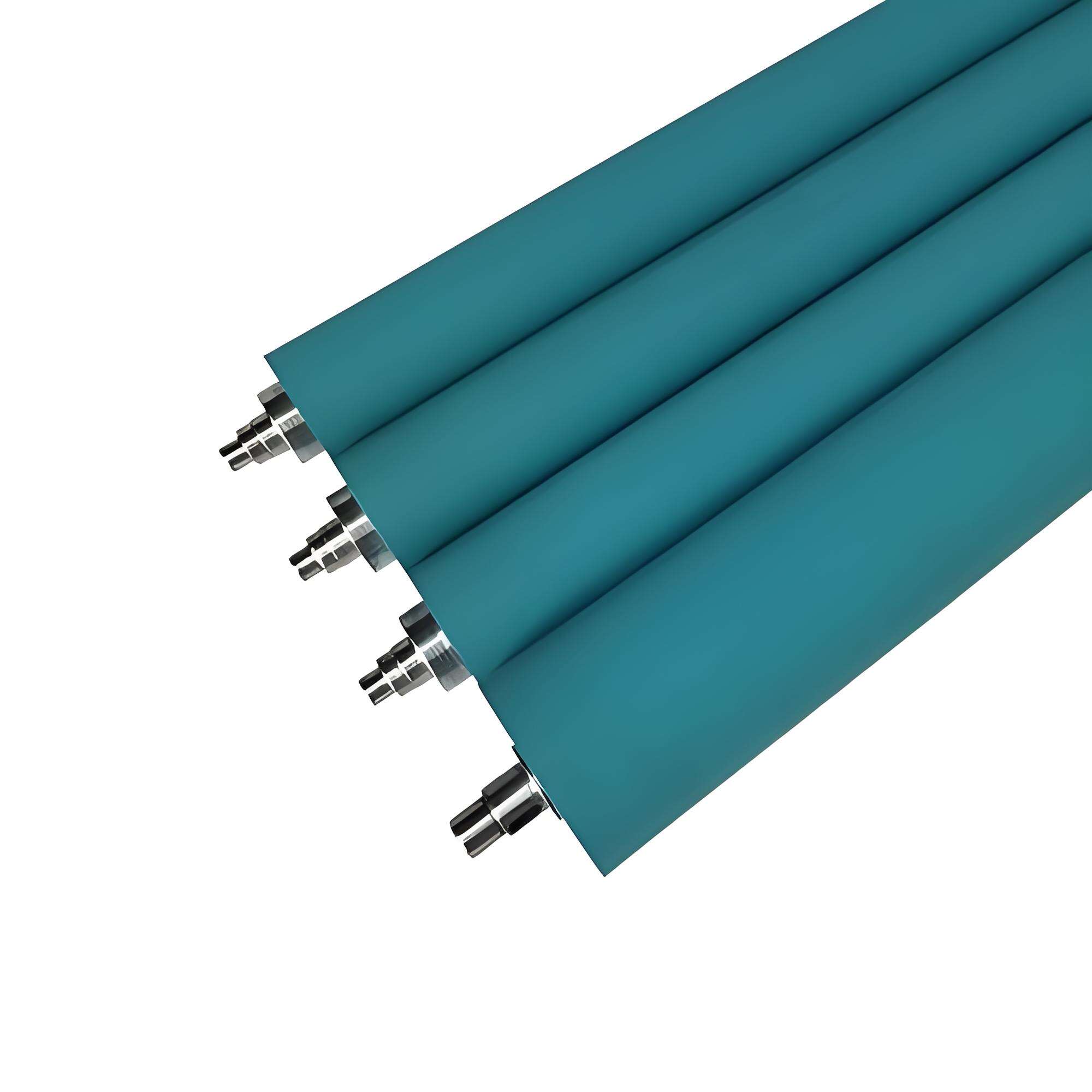

flexible tyre coupling

A flexible tyre coupling represents a crucial mechanical component designed to connect two shafts while accommodating misalignment and reducing vibration transmission. This innovative coupling utilizes rubber or synthetic elastomer elements sandwiched between metal flanges, creating a flexible connection that can absorb shock loads and dampen vibration. The coupling's design allows for three types of misalignment: angular, parallel, and axial, making it extremely versatile in various industrial applications. The rubber element, typically reinforced with fabric or steel cord, provides excellent torsional flexibility while maintaining the necessary strength to transmit torque effectively. These couplings are particularly valuable in applications involving electric motors, pumps, compressors, and other rotating machinery where shaft alignment cannot be maintained perfectly. The design incorporates fail-safe features that ensure continued operation even if the rubber element fails, preventing catastrophic system failure. Modern flexible tyre couplings often include advanced materials and engineering solutions that extend service life and improve performance under demanding conditions. Their ability to operate in both horizontal and vertical orientations, combined with their capacity to handle high torque transmission, makes them indispensable in modern industrial settings.