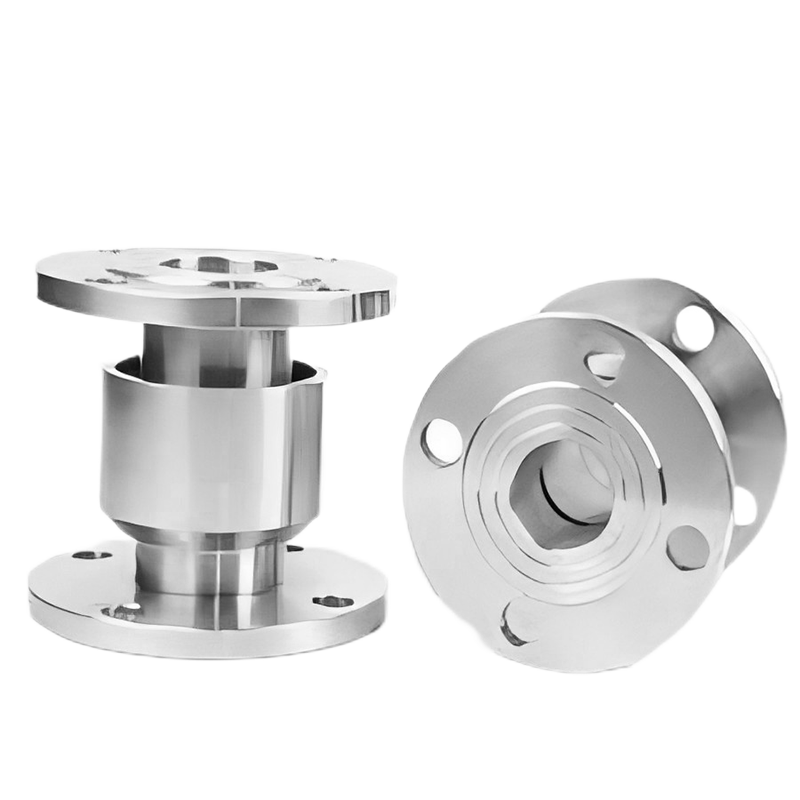

hydraulic rotary swivel joint

A hydraulic rotary swivel joint is a critical mechanical component designed to enable the seamless transfer of hydraulic fluid between stationary and rotating parts of machinery. This sophisticated device serves as a crucial interface in various hydraulic systems, allowing for continuous fluid flow while maintaining optimal pressure levels and preventing leakage. The joint consists of precision-engineered components, including sealed bearings, rotating elements, and specialized sealing systems that work in harmony to ensure reliable performance. What sets the hydraulic rotary swivel joint apart is its ability to maintain fluid integrity during continuous rotation, making it indispensable in applications requiring uninterrupted hydraulic power transmission. These joints are manufactured using high-grade materials and undergo rigorous testing to ensure durability and longevity in demanding industrial environments. The design incorporates advanced sealing technology that prevents fluid contamination and maintains system efficiency, while the precision-machined components ensure smooth rotation and minimal friction. Modern hydraulic rotary swivel joints often feature multiple passages for different hydraulic circuits, allowing for complex fluid routing in a single compact unit.