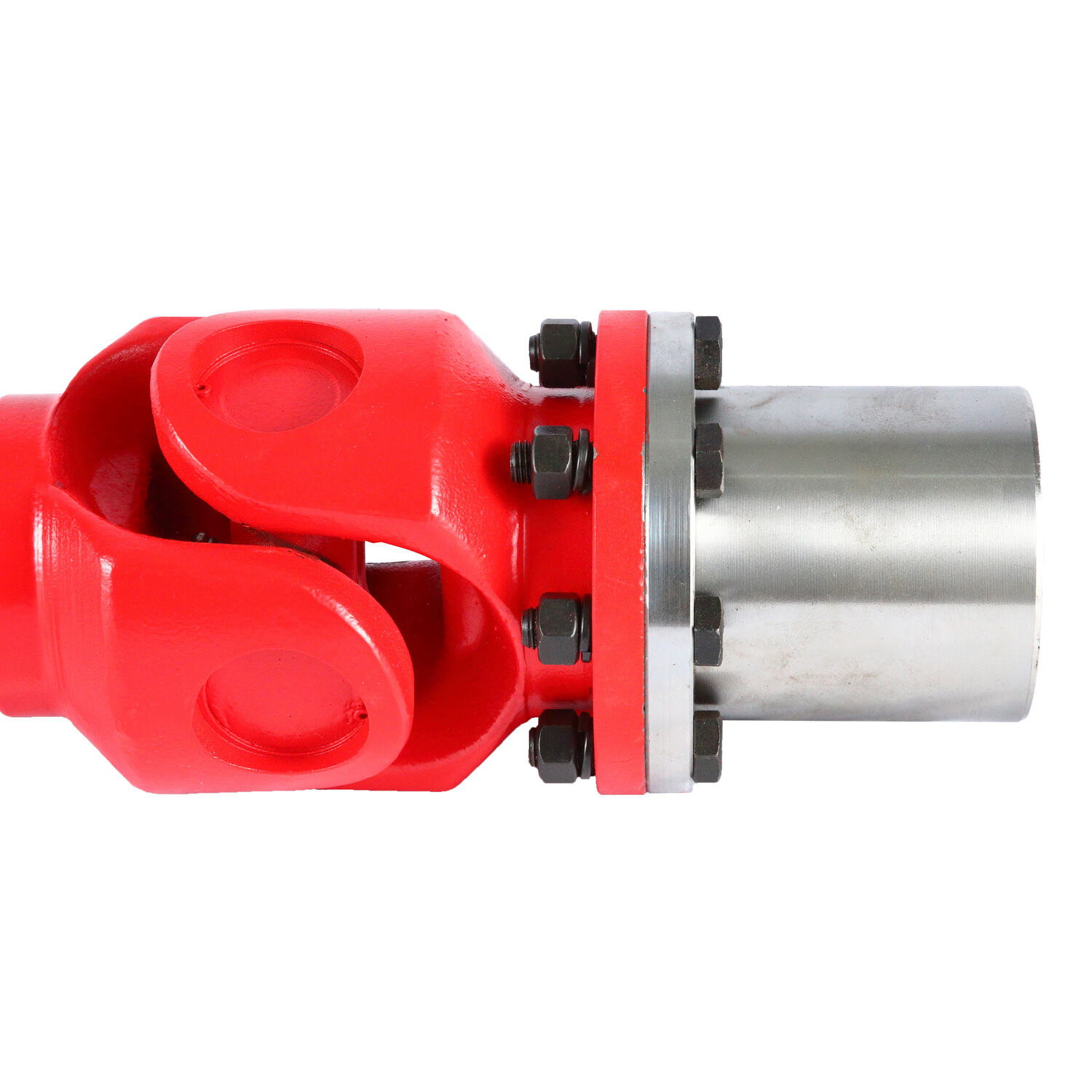

industrial cardan shaft

An industrial cardan shaft is a vital mechanical component that facilitates power transmission between machinery elements that are not directly aligned. This sophisticated piece of engineering, also known as a universal joint shaft, enables the transfer of rotational force across varying angles while maintaining consistent speed and torque. The shaft consists of several key components, including universal joints at both ends, a splined section for length compensation, and a balanced shaft body. The design allows for angular misalignment between the driving and driven components while ensuring smooth operation and minimal vibration. Industrial cardan shafts are engineered to handle high torque requirements and operate efficiently under demanding conditions. They incorporate advanced bearing systems and specialized lubricating mechanisms to ensure longevity and reliability. These shafts are manufactured using high-grade materials, typically heat-treated alloy steel, to withstand severe stress and maintain structural integrity under continuous operation. Modern industrial cardan shafts often feature sophisticated balancing techniques and protective coatings to enhance performance and durability. They are essential in various industrial applications, from heavy machinery and manufacturing equipment to power generation systems and material handling devices.