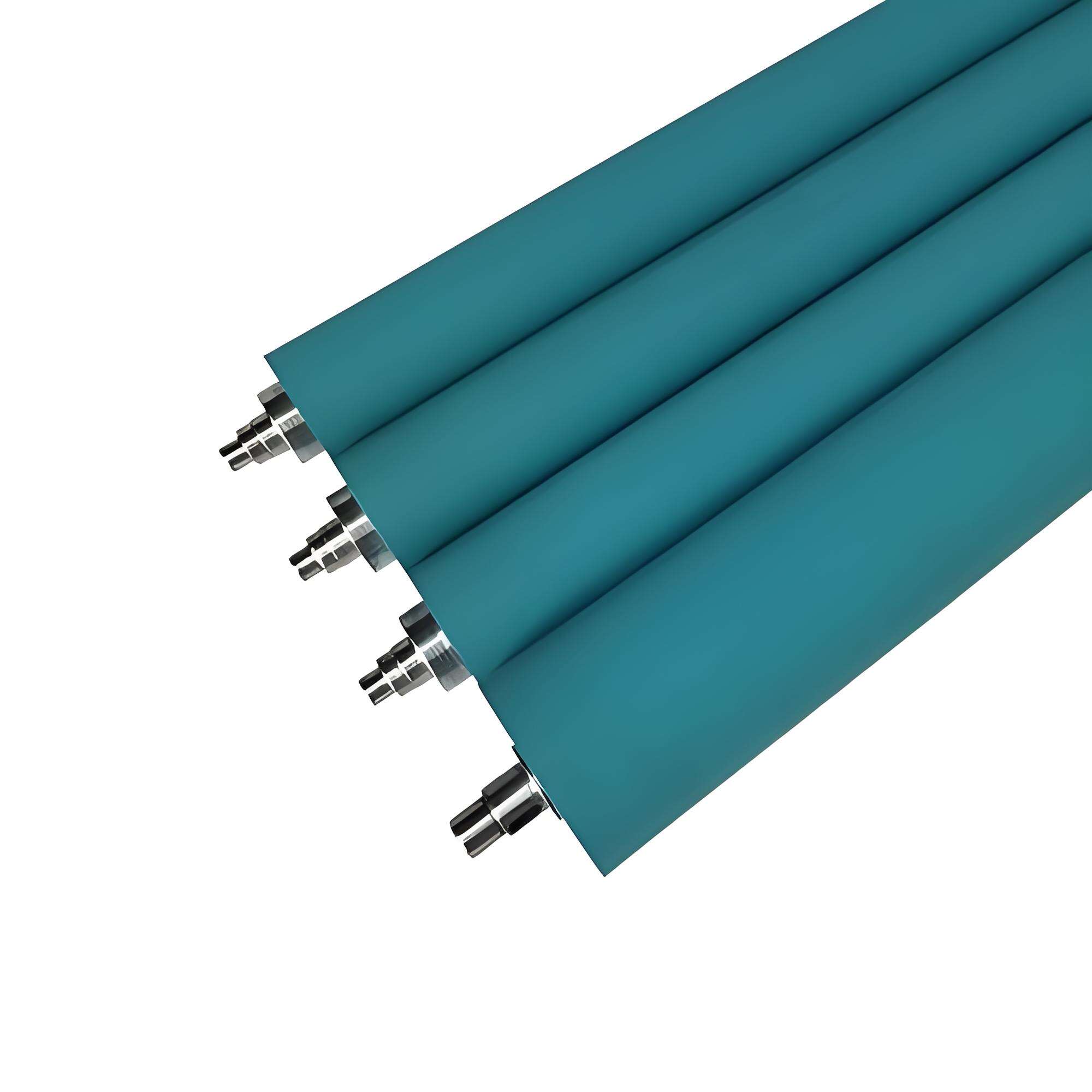

rice mill rubber roller

The rice mill rubber roller stands as a crucial component in modern rice processing technology, engineered specifically for optimal grain handling and processing efficiency. This essential piece of equipment consists of high-quality rubber compounds precisely formulated to maintain consistent hardness and durability throughout its operational lifespan. The roller functions by creating the perfect amount of friction and pressure needed to remove the rice husk without damaging the valuable grain beneath. Its precisely calibrated surface texture ensures uniform processing across the entire roller length, while the specialized rubber composition provides excellent grip and wear resistance. The roller's design incorporates advanced vulcanization techniques that enhance its longevity and maintain consistent performance under various operating conditions. Modern rice mill rubber rollers feature optimized shore hardness ratings, typically ranging from 45 to 65 depending on specific applications, ensuring ideal processing results for different rice varieties. The roller's surface pattern is engineered to maximize contact area while minimizing grain damage, incorporating years of research and development in rice processing technology. These rollers are essential in both small-scale operations and large industrial mills, offering scalable solutions for various production capacities while maintaining high-quality output standards.