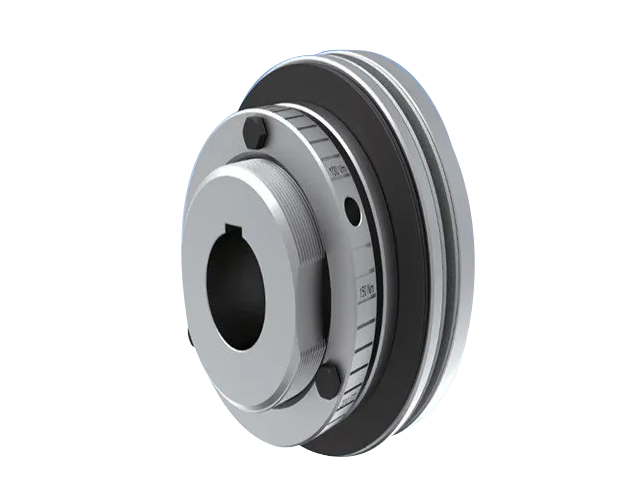

torque limiter clutch

A torque limiter clutch is a sophisticated mechanical device designed to protect machinery and equipment from damage caused by torque overload conditions. This essential component acts as a safety mechanism by automatically disengaging power transmission when torque exceeds predetermined levels. Operating through a combination of precision-engineered friction surfaces and calibrated spring mechanisms, the torque limiter clutch ensures smooth operation while preventing costly equipment damage. The device monitors and controls torque transmission in real-time, responding instantly to overload situations by either slipping or completely disengaging the drive system. Modern torque limiter clutches incorporate advanced materials and design features that enable precise torque control, extended service life, and reliable performance across various industrial applications. These clutches are widely used in manufacturing equipment, conveyor systems, packaging machinery, and heavy industrial applications where consistent torque control is crucial. The ability to adjust torque settings allows for versatile application across different operational requirements, making it an indispensable component in modern machinery design.