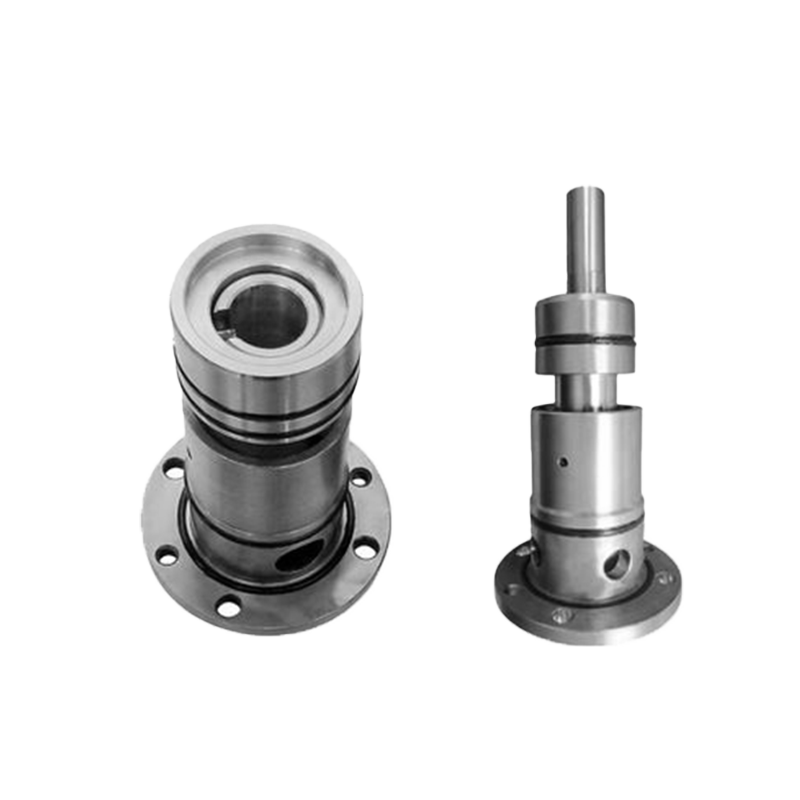

universal quick coupler

A universal quick coupler is an innovative attachment system designed to enhance the versatility and efficiency of construction equipment, particularly excavators and backhoes. This advanced mechanical interface allows operators to switch between various attachments quickly and safely without leaving the cab. The system comprises a robust frame with hydraulically operated locking mechanisms that secure attachments firmly in place. Its universal design accommodates different attachment pins and sizes, making it compatible with multiple brands and models of work tools. The quick coupler features a dual locking system that ensures maximum safety during operation, with both mechanical and hydraulic fail-safe mechanisms. Advanced models include integrated sensors that provide real-time feedback about attachment connection status. The coupler's engineering emphasizes durability with high-grade steel construction and reinforced stress points to withstand demanding job site conditions. This versatile system supports a wide range of attachments, including buckets, hammers, grapples, and specialized tools, enabling rapid transitions between different tasks. The design also maintains optimal breaking force and cutting angle geometry, ensuring performance isn't compromised when compared to direct-mounted attachments.