Strengthening Power Transmission With Cross Couplings

In the field of industrial engineering, the need for secure and efficient torque transfer is constant. Machines must perform under high loads without interruptions, and the components connecting shafts play a decisive role in this process. Cross Couplings stand out as a reliable solution for high-torque applications because of their strength, flexibility, and durability. They are designed to manage alignment challenges, absorb shock loads, and minimize wear, ensuring continuous and stable performance. The adaptability of Cross Couplings makes them valuable across industries such as manufacturing, energy, construction, and robotics, where power transmission is the backbone of daily operations.

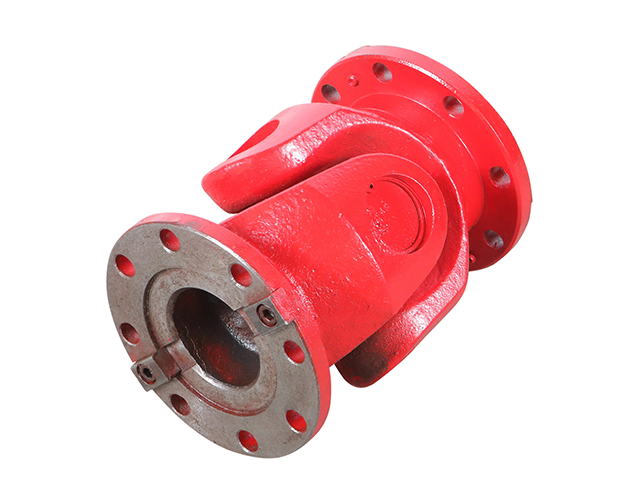

Structural Design of Cross Couplings

Material Selection for Mechanical Strength

Cross Couplings are built from robust materials like alloy steel, stainless steel, or engineered polymers, depending on the operating environment. Strong alloys resist heavy stress, stainless steel prevents corrosion in harsh conditions, and advanced polymers provide lightweight flexibility where needed. The careful choice of material ensures durability and consistent operation in demanding applications.

Flexibility in Misalignment Compensation

Even the most precise machines cannot always maintain perfect shaft alignment. Cross Couplings provide the flexibility to manage angular, axial, and parallel misalignments without reducing performance. By doing so, they protect surrounding components such as bearings and gears from excessive stress.

Distribution of Torque and Load

A vital characteristic of Cross Couplings is their ability to distribute torque evenly. Instead of placing stress on one point of the shaft, they balance forces across the connection. This even distribution reduces fatigue, prevents early damage, and increases the lifespan of equipment.

Performance Advantages of Cross Couplings

Reduction of Vibrations and Operational Noise

Vibration is one of the most common issues in rotating systems. Cross Couplings absorb small movements and disturbances, reducing vibrations and lowering noise. This smoother performance benefits sensitive production environments and improves the working atmosphere.

Resistance to Shock Loads and Sudden Stress

Machines frequently experience abrupt load variations. Cross Couplings are capable of absorbing these sudden forces, preventing equipment failure. Their shock-resistant nature keeps machinery running steadily even under unpredictable operating conditions.

Contribution to Energy Efficiency

By minimizing misalignment and reducing wasted movement, Cross Couplings improve energy transfer between shafts. This not only ensures higher efficiency but also lowers energy consumption over time, which is a key factor in reducing operational costs.

Industrial Applications of Cross Couplings

Heavy-Duty Manufacturing Systems

Manufacturing machinery often operates under extreme pressure for extended periods. Cross Couplings provide stability and protect equipment from strain, ensuring that production continues without interruption. Their contribution to durability makes them a central element in factory operations.

Power Generation and Transmission

In power plants and energy distribution, consistent torque transfer is essential. Cross Couplings ensure stable rotation in turbines, generators, and transmission lines. Their ability to manage stress while maintaining efficiency makes them indispensable in energy systems.

Robotics and Precision Automation

Robotic systems demand precise and repeatable motion. Cross Couplings maintain this precision by allowing small adjustments while keeping torque transfer accurate. They are widely used in automation and robotics where exact positioning is required.

Longevity and Maintenance Benefits

Resistance to Wear and Fatigue

Cross Couplings are engineered to endure repetitive stress without failure. Their design minimizes concentrated wear points, protecting both the couplings and the shafts they connect. This resistance to fatigue leads to longer service life.

Reduction in Maintenance Needs

By decreasing misalignment stress and vibration, Cross Couplings reduce the number of maintenance interventions. This minimizes downtime and allows industries to allocate resources more efficiently. Lower maintenance also translates into cost savings.

Long-Term Value for Equipment Investments

Investing in Cross Couplings brings long-term benefits by reducing repair costs and extending equipment life. Although they may seem like a small part of the machine, their role in ensuring operational continuity makes them a critical investment.

Adaptability and System Integration

Compatibility With Different Shaft Designs

Cross Couplings are compatible with shafts of varying diameters, shapes, and configurations. Their versatile design allows integration into both new and existing systems. This adaptability makes them suitable for a wide range of mechanical setups.

Customization for Specialized Applications

Certain industries face unique challenges, such as extreme temperatures, high humidity, or corrosive chemicals. Cross Couplings can be customized with different materials or coatings to withstand these conditions, ensuring reliable operation in specialized environments.

Scalability for Large and Small Systems

From large turbines to compact automated equipment, Cross Couplings can be scaled to fit different sizes and torque levels. This scalability makes them useful across multiple industries, regardless of system complexity.

Role of Cross Couplings in Sustainable Practices

Energy Conservation Through Efficiency

By maintaining optimal torque transfer and reducing unnecessary energy losses, Cross Couplings support energy conservation. This is increasingly important as industries aim to meet sustainability targets and reduce operational costs.

Extending Machinery Lifespan to Reduce Waste

Sustainability is also linked to equipment longevity. Cross Couplings extend the lifespan of industrial machinery, reducing the need for frequent replacements. This results in less waste and lower resource consumption.

Contribution to Environmentally Responsible Operations

Cross Couplings align with environmentally responsible practices by promoting efficiency, reducing waste, and supporting longer machine cycles. Their durability helps industries move closer to eco-friendly operations.

FAQ

What are the main advantages of Cross Couplings in high-torque applications

Cross Couplings provide durability, misalignment compensation, vibration reduction, and consistent torque transfer, making them highly effective in demanding environments.

How do Cross Couplings improve equipment efficiency

They reduce energy losses by minimizing friction, protect shafts from strain, and ensure smoother torque transfer, which improves overall system efficiency.

Can Cross Couplings be customized for different industries

Yes, Cross Couplings can be manufactured in different sizes and materials, allowing them to operate in environments such as high-temperature, corrosive, or high-load systems.

What long-term benefits do Cross Couplings bring to industrial systems

They extend machine life, reduce downtime, minimize maintenance needs, and improve energy efficiency, offering both performance and financial advantages.