Enhancing Rotational Performance in Demanding Environments

In industrial sectors where torque demands are high and performance is critical, selecting the right coupling is essential. Gear couplings have emerged as a robust and reliable solution in various mechanical systems. Known for their ability to accommodate misalignment and transmit high torque, gear couplings are a preferred choice in heavy-duty applications such as steel mills, paper machinery, mining equipment, and power generation. Their design and function significantly contribute to equipment longevity, reduced maintenance, and consistent operational output.

Torque Transmission and Load Capacity

Superior Torque Handling Capabilities

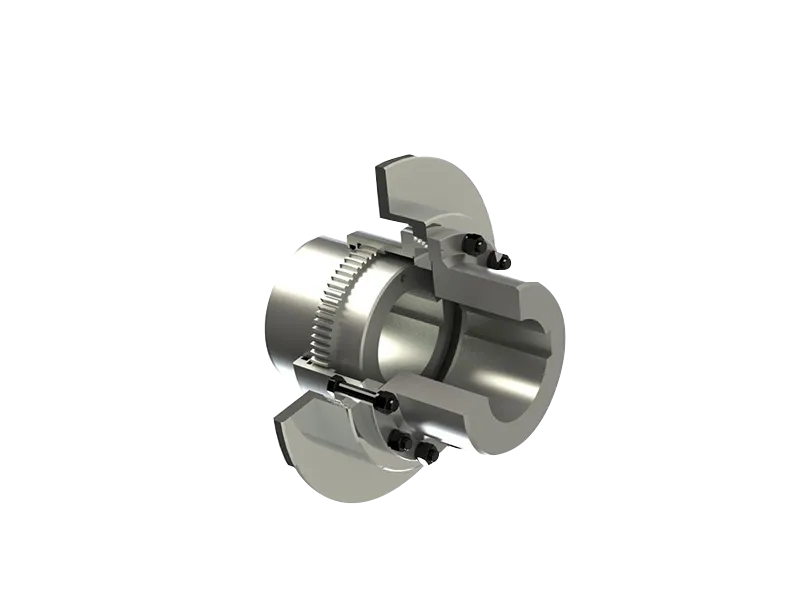

One of the primary reasons gear couplings are favored in industrial applications is their ability to handle high torque. This is made possible by the toothed interface, which creates a strong connection between the shafts. The gear teeth distribute torque evenly across the coupling, preventing stress concentration and reducing the likelihood of mechanical failure.

Support for High Load Applications

Gear couplings are specifically designed to endure the strain of heavy-duty operations. Whether it’s lifting, pressing, or conveying, their structural integrity ensures that load fluctuations do not compromise the alignment or overall system performance. This makes them ideal for high-torque environments where other couplings might fail prematurely.

Misalignment Compensation and Flexibility

Accommodation of Angular and Parallel Misalignments

Industrial environments often experience shaft misalignments due to foundation settling or operational vibrations. Gear couplings are engineered to handle both angular and parallel misalignments without reducing torque transmission capabilities. This flexibility ensures smooth operation even under changing conditions.

Enhanced System Reliability

By compensating for misalignment, gear couplings reduce stress on shafts and bearings. This leads to lower vibration levels, reduced component wear, and increased machine uptime. The result is a more reliable and efficient mechanical system that delivers consistent performance over time.

Durability and Maintenance Efficiency

Long-Lasting Performance

Gear couplings are typically made from high-grade alloy steel and undergo heat treatment processes to enhance strength and wear resistance. With proper lubrication and routine checks, they can function reliably for years in extreme working environments. This longevity is one of the key contributors to their popularity in high-torque applications.

Easy Maintenance and Serviceability

Despite their robust design, gear couplings are easy to maintain. Most designs allow for quick disassembly and reassembly, which minimizes downtime during routine maintenance. Grease or oil-lubricated versions ensure smooth operation, and many models come with built-in inspection ports for easier condition monitoring.

Versatility in Industrial Applications

Broad Compatibility with Equipment Types

Gear couplings can be adapted to a wide variety of machinery setups. Whether it’s motor-to-gearbox, gearbox-to-driven equipment, or even complex multi-shaft systems, these couplings offer seamless integration. Their modularity and range of sizes ensure they can meet specific operational requirements.

Effective Across Multiple Industries

From marine propulsion to cement processing and everything in between, gear couplings prove their worth across sectors. Their adaptability, strength, and ability to withstand harsh environments make them a universal solution for high-demand mechanical connections.

Efficiency and Energy Transfer

Improved Energy Transmission

Gear couplings are designed to transmit rotational energy with minimal loss. The close-fit engagement of gear teeth ensures that the majority of input power reaches the driven equipment. This efficient energy transfer enhances overall system performance and reduces operational costs.

Reduced Operational Downtime

By maintaining alignment and torque consistency, gear couplings help reduce unscheduled maintenance events. This translates to higher productivity and better utilization of equipment. Facilities can run longer between maintenance cycles, optimizing output and profitability.

Customization and Engineering Options

Tailored Designs for Unique Needs

Many manufacturers offer customized gear coupling solutions to match specific torque, speed, and misalignment tolerances. This ensures optimal fit and performance for specialized machinery. Custom gear couplings can also be engineered to work in hazardous or explosive environments.

Integration with Monitoring Technology

Modern gear couplings can be equipped with sensors that monitor temperature, vibration, and alignment. This proactive approach to maintenance helps prevent failures before they occur and supports data-driven decision-making for equipment management.

Environmental and Safety Considerations

Reduced Noise and Vibration

One of the indirect benefits of using gear couplings is the reduction in noise and vibration across connected machinery. This not only protects components but also improves the working environment for operators. Lower noise levels contribute to workplace safety and regulatory compliance.

Enhanced Operator Safety

Reliable gear coupling performance reduces the chances of sudden failures or accidents. Well-maintained gear couplings contribute to a safer operating environment, minimizing risks associated with high-torque equipment.

Cost-Effectiveness Over the Equipment Lifecycle

Lower Total Cost of Ownership

Although gear couplings might have a higher upfront cost compared to other types of couplings, their durability and low maintenance needs result in long-term savings. Facilities experience fewer equipment failures, reduced downtime, and lower repair expenses.

Prolonged Equipment Lifespan

By maintaining proper shaft alignment and reducing component stress, gear couplings contribute to the extended lifespan of connected machinery. This leads to less frequent replacements and a more sustainable operational model.

Enhanced Performance in Critical Systems

Stability Under High Dynamic Loads

In dynamic systems where load conditions change rapidly, gear couplings provide stability and control. Their robust construction allows them to absorb shock and maintain operational integrity, even in fluctuating conditions.

Consistent Output and Process Quality

Maintaining precise shaft alignment and torque delivery ensures that production processes remain consistent. This reliability is crucial in sectors where process quality directly impacts product value and compliance.

Frequently Asked Questions

What makes gear couplings suitable for high-torque applications?

Gear couplings are designed with interlocking teeth that ensure efficient torque transfer while maintaining alignment. This makes them ideal for high-torque, high-load environments.

How often should gear couplings be maintained?

Maintenance frequency depends on the application, but regular inspections every six months and timely lubrication help maximize performance and lifespan.

Are gear couplings compatible with different machinery types?

Yes, gear couplings come in various configurations that can be adapted to motors, gearboxes, pumps, and other equipment types used in diverse industries.

Can gear couplings be customized for specific operational needs?

Absolutely. Many manufacturers provide tailored gear coupling solutions based on specific torque ratings, misalignment tolerances, and environmental conditions.

Table of Contents

- Enhancing Rotational Performance in Demanding Environments

- Torque Transmission and Load Capacity

- Misalignment Compensation and Flexibility

- Durability and Maintenance Efficiency

- Versatility in Industrial Applications

- Efficiency and Energy Transfer

- Customization and Engineering Options

- Environmental and Safety Considerations

- Cost-Effectiveness Over the Equipment Lifecycle

- Enhanced Performance in Critical Systems

- Frequently Asked Questions