Ქრომირებული როლიკები: კოროზიის მიმართ მდგრადობის საბოლოო ამონახსნი

Ინდუსტრიული წარმოების მოწყობილობების წარმოებით ქრომირებული როლიკებით

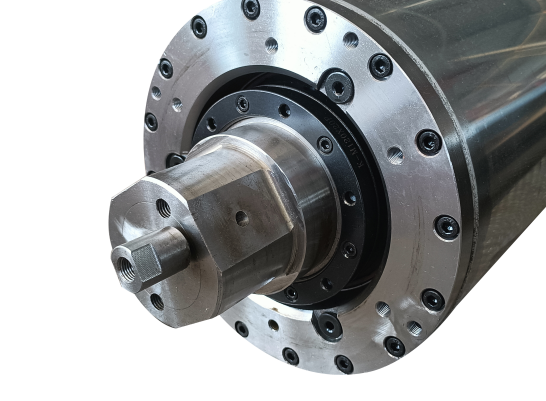

Დღევანდელ მანქანათმშენებლობა და გადამუშავების ინდუსტრიაში, მანქანების მდგრადობა და საიმედოობა პირდაპირ გავლენას ახდენს წარმოების ეფექტურობაზე და ოპერაციულ ხარჯებზე. კომპანიები არასდროს ეძებენ ამონახსნებს, რომლებიც შეძლებენ მათი მანქანების სიცოცხლის გახანგრძლივებას და დაუშვებენ დროის მინიმუმს. Ქრომირებული როლიკები გამოიკვეთა როგორც ერთ-ერთი ყველაზე ეფექტური გამოобрება ამ მოთხოვნების დასაკმაყოფილებლად. უნიკალური ზედაპირის დასრულებით, რომელიც აერთიანებს სიმაგრეს, გლუვებას და ქიმიური მოხსნის წინააღმდეგ მდგრადობას, ეს როლიკები ხელს უწყობს იმ ინდუსტრიებს, სადაც ზუსტი და გამძლეობა არის არსებითი. ბეჭდვიდან და შეფუთვამდე, მეტალურგიიდან დაწუნების დამუშავებამდე, Ქრომირებული როლიკები სწრაფად ვრცელდება მისი როლი. ისინი მხოლოდ უფრო გლუვი ოპერაციებს ხელს უწყობს, არამედ მნიშვნულად ამცირებს შეცვლის სიხშირეს, რაც უზრუნველყოფს მაღალი ხარისხის ექსპლუატაციაში გრძელვადიან ინვესტიციებს.

Ქრომირებული როლიკების ძირითადი მახასიათებლები

Კოროზიის წინააღმდეგობა

Ხრომირებული როლიკების ერთ-ერთი ყველაზე მნიშვნელოვანი მახასიათებელი არის მათი განსაკუთრებით მაღალი წინააღმდეგობა კოროზიის მიმართ. როდესაც არადამცავი როლიკები ხვდებიან საფრთხის შემცველ გარემოში, მათ შორის ტენიანობას, ხსნელებს და ქიმიკატებს, ისინი სწრაფად იშლებიან. ხრომის დალექვა ქმნის დამცავ ბარიერს, რომელიც ანელებს ოქსიდაციას და ნაკლებად იწვევს მასში ნაკვებებს, რითაც უზრუნველყოფს როლიკის სტრუქტურული მთლიანობის შენარჩუნებას. ეს თვისება განსაკუთრებით მნიშვნელოვანია იმ ინდუსტრიებში, როგორიცაა ქაღალდის წარმოება და საკვების დასაფარი, სადაც ტენიანობასთან ურთიერთქმედება არის გაუმართლებელი.

Სიმტკიცე და გამძლეობა

Ქრომით დაფარული როლიკების განმსაზღვრელი ხასიათის ერთი სხვა მახასიათებელი არის მაღალი ზედაპირის მაგრივე. დაფარვის პროცესი მნიშვნულად ამაღლებს როლიკის ზედაპირის მაგრივეს, ხშირად მიაღწევს მაჩვენებლებს, რომლებიც აღემატება არამუშაობის ფოლადს. ეს უზრუნველყოფს როლიკების მაღალ მექანიკურ მდგრადობას ხაზების, ჩანგლების და აბრაზიული ზიანის მიმართ, რომლებიც შეიძლება მოხდეს მძიმე პირობებში. შედეგად, ისინი შენარჩუნებენ თავისი ფუნქციონალური თვისებებს გაცილებით გრძელი ვადით, რაც ამცირებს მომსახურების და შეცვლის სიხშირეს.

Ზედაპირის დამუშავება და გლუვება

Ქრომით დაფარული როლიკების გლუვი ზედაპირი უზრუნველყოფს უკეთეს პროდუქტის მართვას და მასალის დამუშავების ერთგვაროვნობას. უმისოდ თუ ის მართავს ნაზავ ქაღალდის ფურცლებს ან მუშაობს მტკიცე მეტალის ფურცლებზე, ერთგვაროვანი დასრულება ამცირებს ხახუნს და ამცირებს პროდუქტის ნაკლის რისკს. ეს გლუვება ასევე უზრუნველყოფს ზუსტ მოწყობას მაღალსიჩქარიან მანქანებში, სადაც უმცირესი ზედაპირის ნაკლი შეიძლება დაარღვიოს წარმოების ხარისხი.

Ქრომით დაფარული როლიკების გამოყენება სხვადასხვა ინდუსტრიაში

Ბეჭდვისა და გაყიდვის ინდუსტრია

Ბეჭდვისა და გაყიდვის ინდუსტრიაში ქრომით დაფარეული როლიკები ფართებით გამოიყენება, რადგან ისინი უზრუნველყოფენ მაღალსიჩქარიან ოპერაციებს სიზუსტის დაცოდების გარეშე. ისინი უზრუნველყოფენ საჭირო გლუვედ ინკის გადატანას ან ნაზი გაყიდვის ფირების მუშაობას, რაც უზრუნველყოფს მუდმივ შედეგებს გრძელ სერიებში. ასევე, როლიკების მაღალი მა endure მინიმუმამდე აქვეითს დროს, რომელიც არის აუცილებელი ინდუსტრიებში, სადაც დიდი მოცულობის დამუშავება ხდება უწყვეტად.

Ტექსტილისა და მასალის დამუშავება

Ტექსტილის წარმოება დამოკიდებულია იმ მანქანებზე, რომლებიც ახლო კონტაქტში არიან ნაზი მასალებთან. ქრომით დაფარეული როლიკები ასრულებენ მნიშვნელოვან როლს გლუვი, მაგრამ მაიძულე ზედაპირის მიწოდებაში, რაც არ ზიანებს მასალას. მათი წინააღმდეგობა ცვეთისა უზრუნველყოფს უწყვეტი მუშაობის შესაძლებლობას სიზუსტის დაკარგვის გარეშე, რაც არის მნიშვნელოვანი მასალის ხარისხის შესანარჩუნებლად წარმოების სხვადასხვა სტადიებზე.

Მეტალგადამუშავება და მძიმე ინდუსტრიები

Მეტალის დამუშავების სფეროში ქრომით დაფარული როლიკები უნდა გაუძლონ მძიმე დატვირთვას, მაღალ ტემპერატურას და აბრაზიულ პირობებს. ქრომის დაფარვა უზრუნველყოფს როგორც საჭირო მარტივს, ასევე წინააღმდეგობას გარემოს გამოწვევების მიმართ, როგორიცაა სითხის გამტარი სითხეების აორთქლება და ჟანგვა. ეს თვისებები ხდის მათ არაგამოცვლილს პროცესებში, როგორიცაა როლიკების მორგება, მოკრულობა და ფურცლის მუშაობა, სადაც საიმედოობა მთავარია.

Ქრომით დაფარული როლიკების სარგონი გრძელვადიან გამოყენებისას

Შემცირებული ტექნიკური ხარჯები

Ქრომით დაფარული როლიკების გამოყენების ერთ-ერთი მთავარი სარგოა შესანიშნავად შემცირებული მომსახურების ხარჯები. რადგან როლიკები წინააღმდეგობას უწევს ცვეთას და კოროზიას, ისინი არ საჭიროებს ხშირ შეცვლას ან შეკეთებას. ეს პირდაპირ გადადის ფულის დაზოგვაზე და საშუალებას იძლევა კომპანიებს ასახლის რესურსები გამოიყენონ საწარმოს სხვა სფეროებში.

Გაუმჯობესებული პროდუქტიულობა

Ქრომის დაფაფრის როლიკების მაღალი გამძლეობა და სიზუსტე უზრუნველყოფს საერთო წარმოებიანობის გაზრდას. მანქანების გამოყენება ასეთი როლიკებით უზრუნველყოფს მათ გრძელვადიან და უწყვეტი მუშაობას მაღალი სიჩქარით, რაც ამაღლებს გამოშვების მაჩვენებელს. გარდა ამისა, მუდმივი მუშაობის შედეგად პროდუქტის ხარისხი მუდმივად რჩება, რაც ამცირებს ნარჩენებს და ხარჯებს ხარისხის გასაუმჯობესებლად.

Გრძელვადიანი ღირებულების შექმნა

Მიუხედავად იმისა, რომ ქრომის დაფაფრის როლიკები თავდაპირველად უფრო მაღალ ინვესტიციებს მოითხოვს არადაფაფრიან როლიკებთან შედარებით, მათი გამძლეობა და საიმედოობა გრძელვადიან პერიოდში უზარმაზარ ღირებულებას ქმნის. ბიზნესის განვითარებას უწყობს როგორც დაუსვენებელი მუშაობა და შეცვლების სიმცირე, ასევე პროდუქტის მუდმივი ხარისხის გამო შესაძლო რეპუტაციის გაუმჯობესებაც. გრძელვადიანი ღირებულება კი ადასტურებს იმას, რომ ქრომის დაფაფრის როლიკები მხოლოდ კომპონენტებზე მეტს წარმოადგენს - ისინი თანამედროვე წარმოების სტრატეგიული აქტივებია.

Ქრომის დაფაფრის როლიკების ტექნიკური მახასიათებლები

Დაფაფრის სისქე და ხარისხი

Ქრომით დაფარებული როლიკების ეფექტურობა მნიშვნელოვნად დამოკიდებულია დაფარვის სისქეზე და ხარისხზე. მაღალხარისხიანი დაფარვა უზრუნველყოფს ერთგვაროვნებას და მუდმივ დაცვას როლიკის ზედაპირზე. სისქის არასაკმარისობა ან ცუდი დანალოგი შეიძლება გამოიწვიოს ადრეული ცვეთა, რაც უკიდურესად ასუსტებს ტექნოლოგიის უპირატესობებს.

hop მოწყობილობასთან თავსებადობა

Ქრომით დაფარებული როლიკების არსებულ მანქანებში ინტეგრირებისას უნდა განხილულ იქნას თავსებადობა. განზომილებები, წონა და ზედაპირის მოთხოვნები უნდა შეესაბამოს მოწყობილობის ექსპლუატაციურ მოთხოვნებს. სწორი პირდაპირება უზრუნველყოფს უსწრაფეს ინტეგრირებას და მაქსიმალურ შესრულებას.

Მოვლა-პატრონობის წესები

Მიუხედავად იმისა, რომ ქრომით დაფარებული როლიკები საკმარისად მაგარია, მათი სიცოცხლის გასაგრძელებლად საჭიროა მაინც შესაბამისი მოვლა. ხშირი გასუფთავება, მონადირეობა და შემოწმება შეიძლება დაგვეხმაროს მცირე პრობლემების არიდებაში, რათა არ გადაიზარდოს უფრო მარგი პრობლემებში. პროაქტიული მოვლის განრიგი ამაღლებს ეფექტურობას და უზრუნველყოფს კოროზიისა და ცვეთის საწინააღმდეგო დაცვის უწყვეტობას.

Გარეგნული და მარტივი საშუალებები

Გაფართოებული მოწყობილობის სიცოცხლე

Ქრომით დაფარული როლიკები მრეწველობითი მანქანების სამუშაო ვადის გახანგრძლივებას უზრუნველყოფს, რაც ამცირებს ახალი კომპონენტების შესყიდვისა და წარმოების სიხშირეს. ეს პირდაპირ უწყობს შესაბამის ძალისხმევებს ბუნებრივი რესურსების მოხმარების შესამსუბუქებლა და ნარჩენების მოცულობის შესამცირებლად.

Ოპერაციებში ენერგოეფექტურობა

Საშუალებას აძლევს მანქანების ენერგომოხმარების შესამსუბუქებლად. ხოლო დროის განმავლობაში ეს ხელს უწყობს გრინ პროდუქციის პროცესების განვითარებას მანქანების საერთო ენერგომოხმარების შემცირებით.

Გამეორებითი გადამუშავება და ქრომირების პოტენციალი

Ქრომით დაფარული როლიკების საწყისი ფენის გასვლის შემდეგ ხშირად ხდება მათი აღდგენა ქრომირების პროცესის საშუალებით. ეს უზრუნველყოფს მათ გამძლეობას, რადგან შეიძლება გამოყენებულ იქნას ძირითადი მასალა, რაც ამცირებს გარემოზე ზემოქმედებას სრულიად ახალი როლიკების წარმოებისას.

Ქრომით დაფარული როლიკების მომავალი განვითარება

Მოწინავე დაფარვის ტექნოლოგიები

Ახალგაზრდა ტექნოლოგიები ამაღლებს ქრომის დალექვის პროცესების ეფექტურობას და გარემოს დაცვის მიმართ საუკეთესო მიდგომებს. ასეთი მიღწევები შეიძლება მოიცავდეს ალტერნატიული დალექვის მასალებს ან გარემოს დააზიანებელი მეთოდების გარეშე იმავე მდგრადობის მიწოდებას.

Ინტელექტუალურ წარმოებასთან ინტეგრირება

Როდესაც ინდუსტრიები გადადის გონივრულ წარმოებაზე და ავტომატურობაზე, ქრომით დაფარეული როლიკების განვითარებაც მიმდევრობით მოხდება. გაუმჯობესებული ზედაპირის დამუშავება, სენსორებთან ურთიერთქმედების შესაძლებლობის მქონე საფარი და ზუსტი რობოტებისთვის შექმნილი როლიკები მომავალში სტანდარტად იქნება მიჩნეული.

Ინდუსტრიების მიხედვით გავრცელებული გამოყენება

Ქრომით დაფარებული როლიკები უკვე დამკვიდრებულია ბეჭდვის, ტექსტილის და მეტალურგიის სფეროში, მაგრამ საკვების მასალების დამუშავებაში, ფარმაცევტიკაში და აღდგენითი ენერგეტიკის სექტორებში ისინი უფრო მეტად გამოიყენებიან. ამ როლიკების მრავალფეროვნება უზრუნველყოფს მათ განმავლობას ახალგაზრდა ინდუსტრიებში.

Ხელიკრული

Რა უზრუნველყოფს ქრომით დაფარეული როლიკების კოროზიის მიმართ მდგრადობას

Ქრომის თავსატარი არის დამცავი ფენა, რომელიც აფერხებს ოქსიდაციას და იცავს როლიკს ტენიანობისა და ქიმიკატებისგან.

Როგორი ხანგრძლივობით შეიძლება იყოს ქრომით დაფარეული როლიკების მუშაობა

Მათი სწორი მოვლის შემთხვევაში, ისინი რამდენიმე წელზე მეტს იმუშავებენ არაფარეული როლიკების ვიდრე, გამოყენების და მუშაობის პირობების დამოკიდებულებით.

Შეიძლება თუ არა ქრომით დაფარეული როლიკების აღდგენა მოხმარების შემდეგ

Დიახ, ბევრი როლიკის შეუძლია გაიაროს ხელახლა დაფარვის პროცესი, რითაც გაიზარდება მათი სამსახურის ვადა და შემცირდება შეცვლის ხარჯები.

Გარემოს დაცვის მხრივ ვარგისია თუ არა ქრომით დაფარეული როლიკების გამოყენება

Ისინი უწყობენ შემსრულებელს მანქანების სიცოცხლის გასაგრძელებლად, ნარჩენების შესამცირებლად და ხელს უწყობენ გამეორებით გამოყენებასა და ხელახლა დაფარვას.

Შინაარსის ცხრილი

- Ინდუსტრიული წარმოების მოწყობილობების წარმოებით ქრომირებული როლიკებით

- Ქრომირებული როლიკების ძირითადი მახასიათებლები

- Ქრომით დაფარული როლიკების გამოყენება სხვადასხვა ინდუსტრიაში

- Ქრომით დაფარული როლიკების სარგონი გრძელვადიან გამოყენებისას

- Ქრომის დაფაფრის როლიკების ტექნიკური მახასიათებლები

- Გარეგნული და მარტივი საშუალებები

- Ქრომით დაფარული როლიკების მომავალი განვითარება

- Ხელიკრული