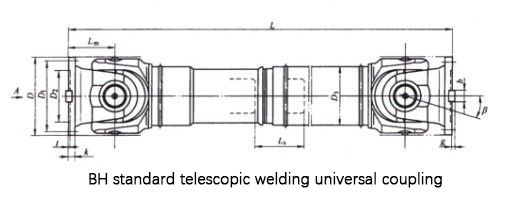

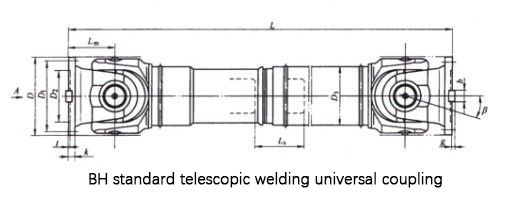

SWC-BH standard telescopic welding universal coupling: efficient transmission solutionProduct Overview

SWC-BH standard telescopic welded universal coupling is a high-performance mechanical transmission component, widely used in metallurgy, lifting, engineering transportation, mining, petroleum, shipbuilding, coal, rubber, papermaking machinery and other heavy machinery industries. Its core function is to connect two shafts and transmit torque, while compensating for axial, radial and angular displacements caused by manufacturing errors, installation errors, shaft deformation, temperature changes and other factors .

Main Features

-

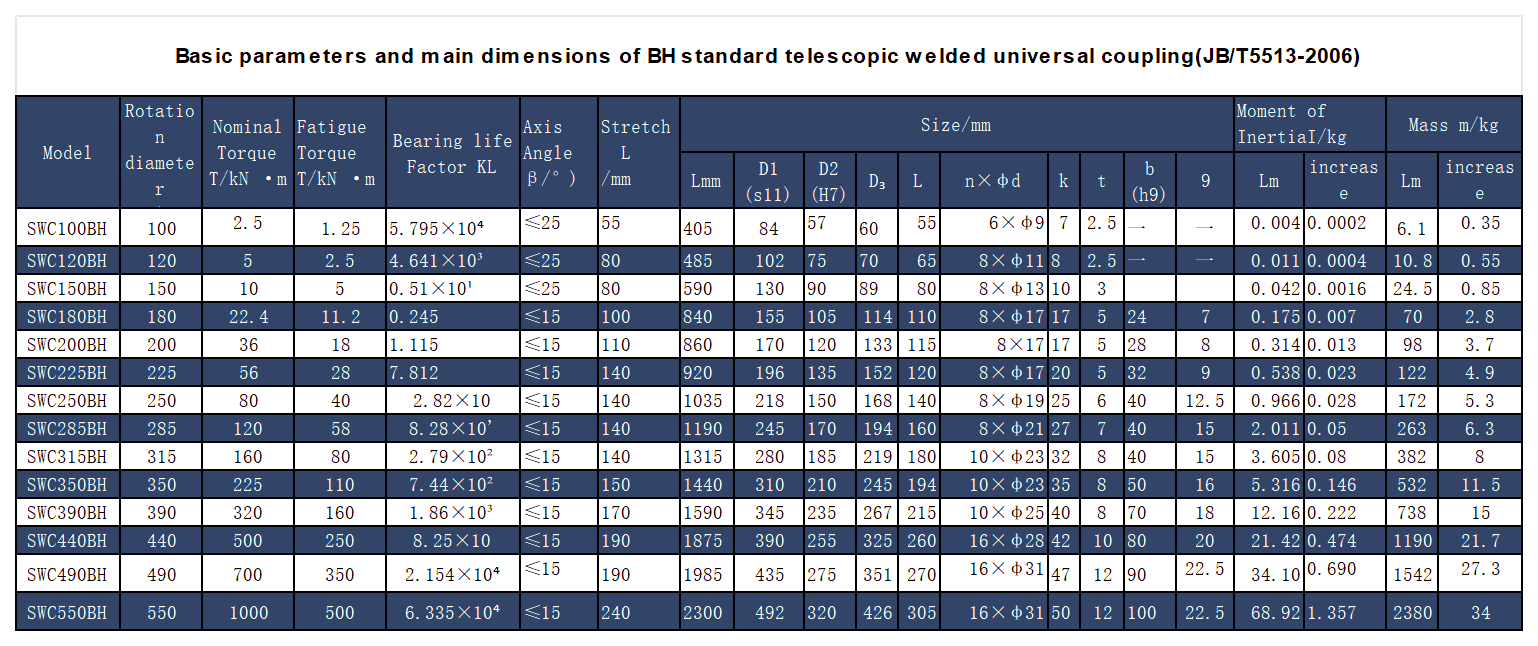

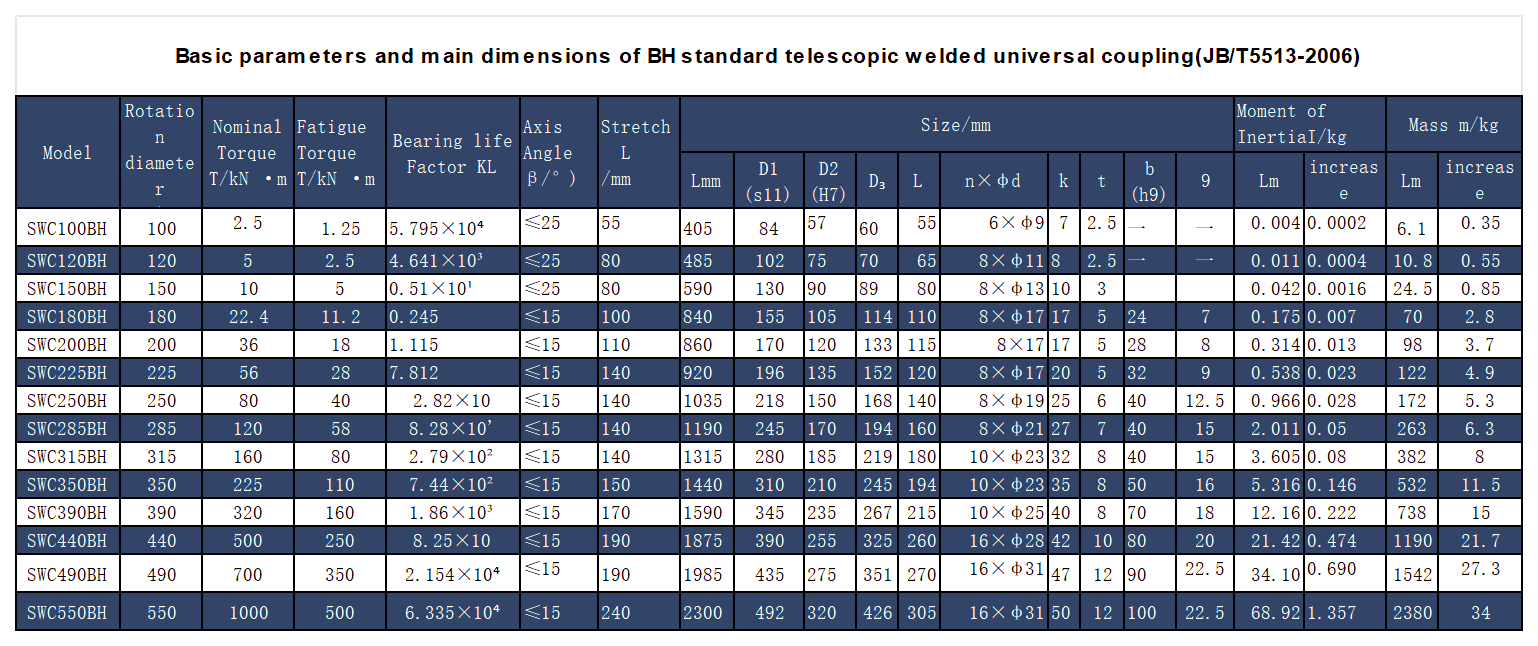

Large angle compensation capability : The axis angle of SWC-BH universal coupling can reach 15°~25°, which is suitable for shaft transmission under complex working conditions .

-

Compact structure : The integrated fork head design enhances the reliability and stability of operation .

-

High load-bearing capacity : Compared with other couplings of the same swing diameter, SWC-BH type can transmit greater torque and is particularly suitable for equipment with limited swing diameter .

-

High-efficiency transmission : The transmission efficiency is as high as 98%-99.8%, with significant energy-saving effect, suitable for high-power transmission scenarios .

-

Smooth operation : low noise design, easy installation and maintenance, suitable for long-term high-intensity use .

Application Areas

SWC-BH universal coupling is suitable for the following industries:

-

Metallurgical industry : used for rolling mills, continuous casting machines and other equipment.

-

Lifting and transportation : suitable for heavy equipment such as cranes and conveyors.

-

Mining machinery : used for crushers, ball mills and other equipment.

-

Shipbuilding industry : suitable for propulsion shafting and steering gear systems.

-

Petrochemical industry : used for pumps, compressors and other equipment 312 .