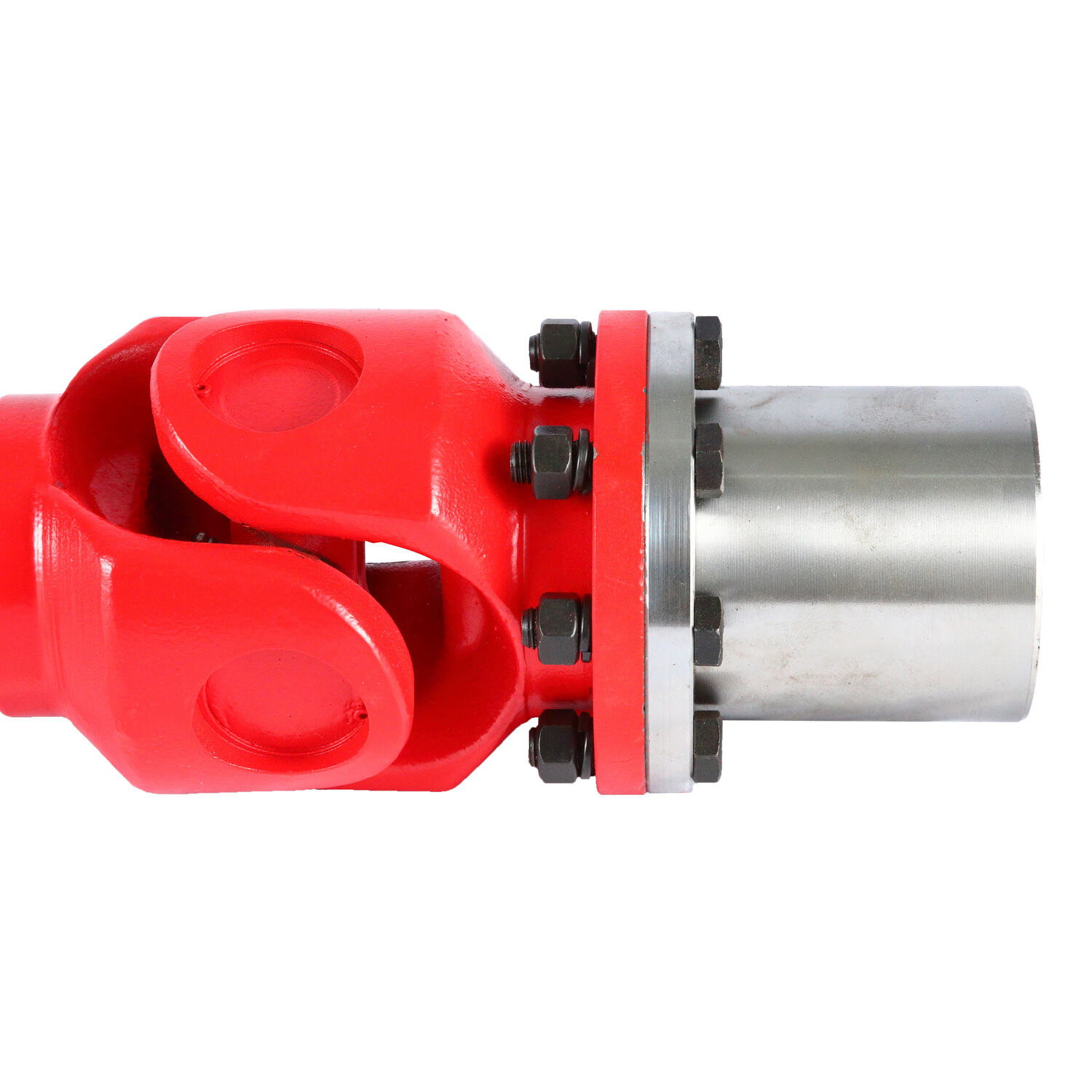

cardan joint drive shaft

The cardan joint drive shaft is a critical mechanical component that enables the transmission of rotational power between non-aligned shafts. This sophisticated mechanism consists of two yokes connected by a cross-shaped intermediate member, allowing for angular misalignment while maintaining smooth power transfer. The design incorporates precision-engineered bearings and robust materials to ensure reliable performance under various operating conditions. Essential in automotive, industrial, and marine applications, the cardan joint drive shaft accommodates both angular and axial movements, making it invaluable in systems where perfect alignment is impossible or impractical. The shaft's ability to handle high torque loads while operating at various angles has made it a fundamental component in modern machinery. Its versatility extends to applications ranging from vehicle powertrains to industrial processing equipment, where it effectively manages power transmission across different planes. The cardan joint's unique design allows for operational flexibility while maintaining mechanical efficiency, reducing wear and extending service life. Modern manufacturing techniques have further enhanced its reliability through improved materials and precision engineering, resulting in better performance and durability.