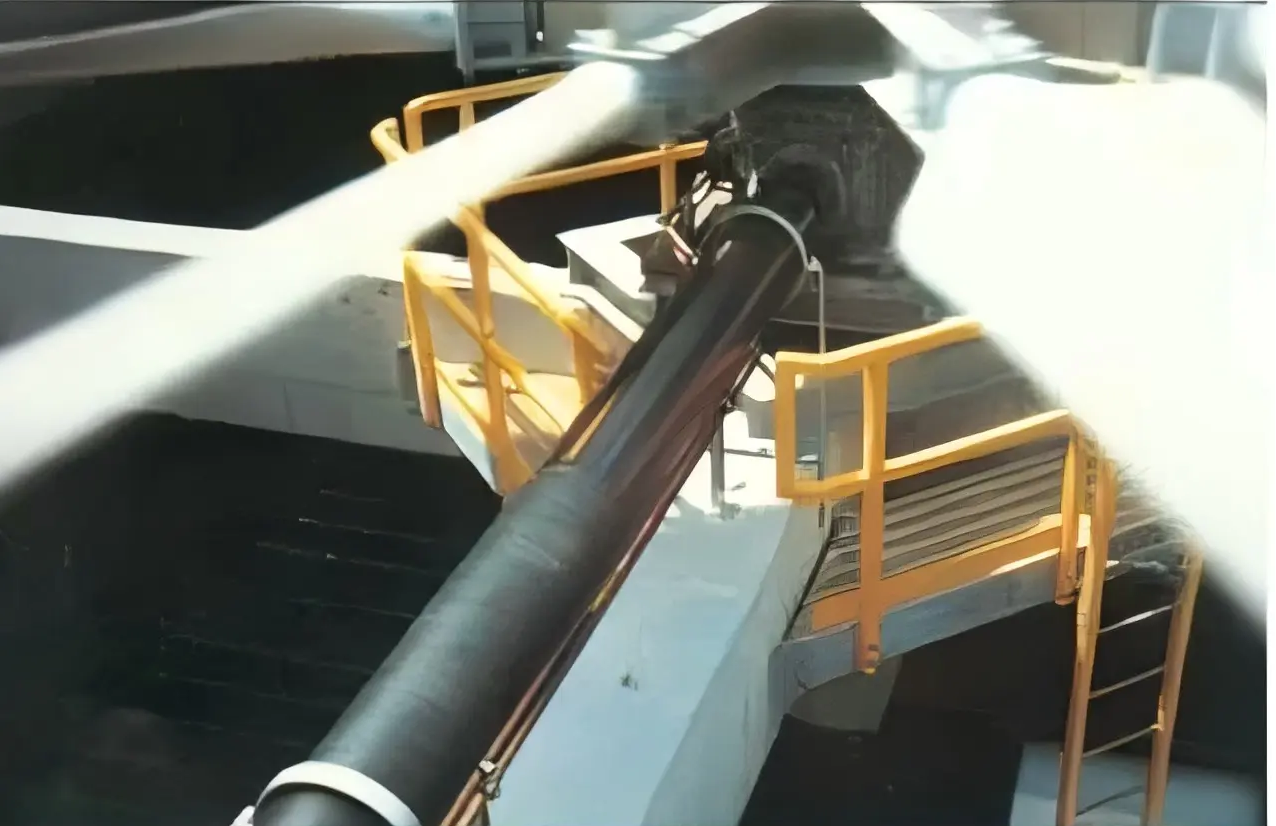

cooling tower coupling manufacturer

A cooling tower coupling manufacturer specializes in designing and producing high-quality power transmission components essential for cooling tower operations. These manufacturers employ advanced engineering techniques and precision manufacturing processes to create reliable, durable couplings that ensure smooth power transfer between driving and driven equipment in cooling tower systems. Their products are designed to withstand challenging environmental conditions, including exposure to moisture, temperature variations, and continuous operation. The manufacturing process incorporates state-of-the-art materials and quality control measures to ensure optimal performance and longevity. These couplings are critical components that facilitate the efficient operation of cooling tower fans, pumps, and other rotating equipment. The manufacturer's expertise extends to providing customized solutions for various cooling tower applications, from industrial processes to HVAC systems in commercial buildings. They utilize modern production facilities equipped with advanced machinery and testing equipment to maintain consistent product quality and meet international standards. The manufacturer's commitment to innovation drives continuous improvement in coupling design, materials, and manufacturing processes, resulting in products that offer enhanced reliability and reduced maintenance requirements.