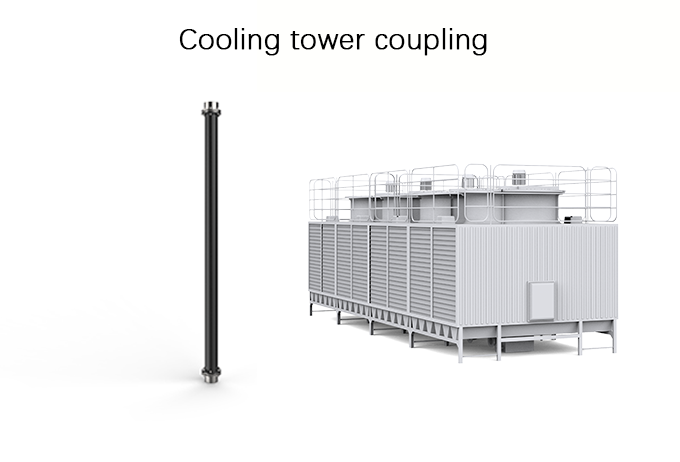

marley cooling tower coupling

The Marley cooling tower coupling represents a crucial component in industrial cooling systems, specifically engineered to ensure optimal performance and reliability in cooling tower operations. This specialized coupling serves as a vital connection point between the motor and fan drive shaft, facilitating smooth power transmission while accommodating misalignment and vibration. Engineered with precision, it features advanced materials and design elements that enhance durability and minimize maintenance requirements. The coupling's construction typically incorporates flexible elements that absorb shock loads and compensate for both angular and parallel misalignment, ensuring consistent operation even under challenging conditions. Its design promotes easy installation and maintenance, reducing downtime and operational costs. The coupling's ability to handle high torque loads while maintaining proper alignment is essential for the efficient operation of cooling tower systems. Furthermore, it incorporates features that protect against environmental factors, including moisture and temperature variations, making it suitable for diverse industrial applications. The Marley cooling tower coupling has become an industry standard, particularly in large-scale industrial cooling operations, power plants, and HVAC systems where reliability and performance are paramount.