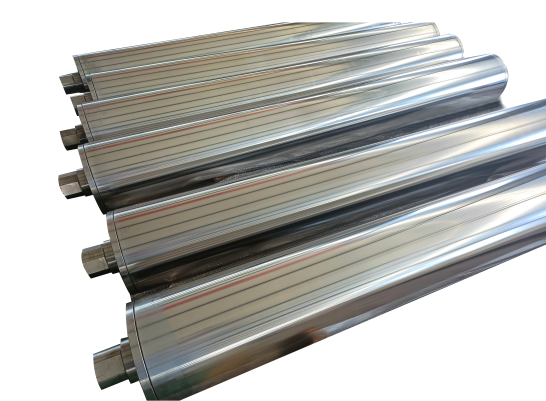

hard chrome roller

Hard chrome rollers represent a pinnacle of industrial engineering, featuring a precision-engineered steel core enhanced with a sophisticated chrome plating process. These rollers are specifically designed to deliver exceptional performance in demanding industrial applications, with chrome layer thicknesses typically ranging from 0.05mm to 0.5mm. The electroplating process creates a remarkably hard surface that achieves a hardness rating of up to 70 HRC, significantly enhancing the roller's durability and wear resistance. The surface finish can be customized to meet specific requirements, ranging from mirror-smooth to textured patterns, making these rollers versatile across various industries. Hard chrome rollers excel in applications requiring precise material handling, consistent pressure distribution, and resistance to corrosive environments. They are instrumental in printing, paper processing, textile manufacturing, and metal forming operations, where their superior surface properties ensure consistent product quality and extended service life. The chrome plating provides excellent release properties, reducing material adhesion and minimizing maintenance requirements while maintaining dimensional stability under varying operating conditions.