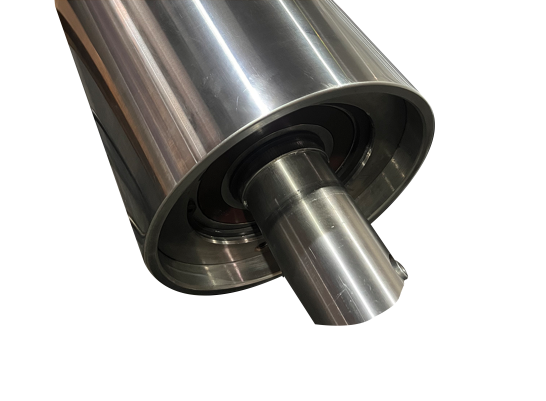

chrome plated roller

Chrome plated rollers represent a pinnacle of industrial engineering, combining durability with precision performance. These essential components feature a hard chromium coating applied through an electroplating process, resulting in a surface that exhibits exceptional wear resistance and dimensional stability. The chrome plating, typically ranging from 0.0002 to 0.01 inches in thickness, creates a smooth, mirror-like finish that significantly reduces friction and extends the roller's operational lifespan. These rollers find extensive applications across various industries, from printing and paper processing to textile manufacturing and metal forming operations. The chrome plating process enhances the base material's properties, providing superior corrosion resistance while maintaining tight dimensional tolerances. The rollers operate effectively in diverse environmental conditions, handling both high-temperature applications and exposure to corrosive substances. Their precise engineering ensures consistent performance in continuous operation scenarios, making them ideal for high-speed production lines and critical manufacturing processes. The surface hardness achieved through chrome plating typically ranges from 66 to 70 on the Rockwell C scale, providing exceptional resistance to wear and abrasion.