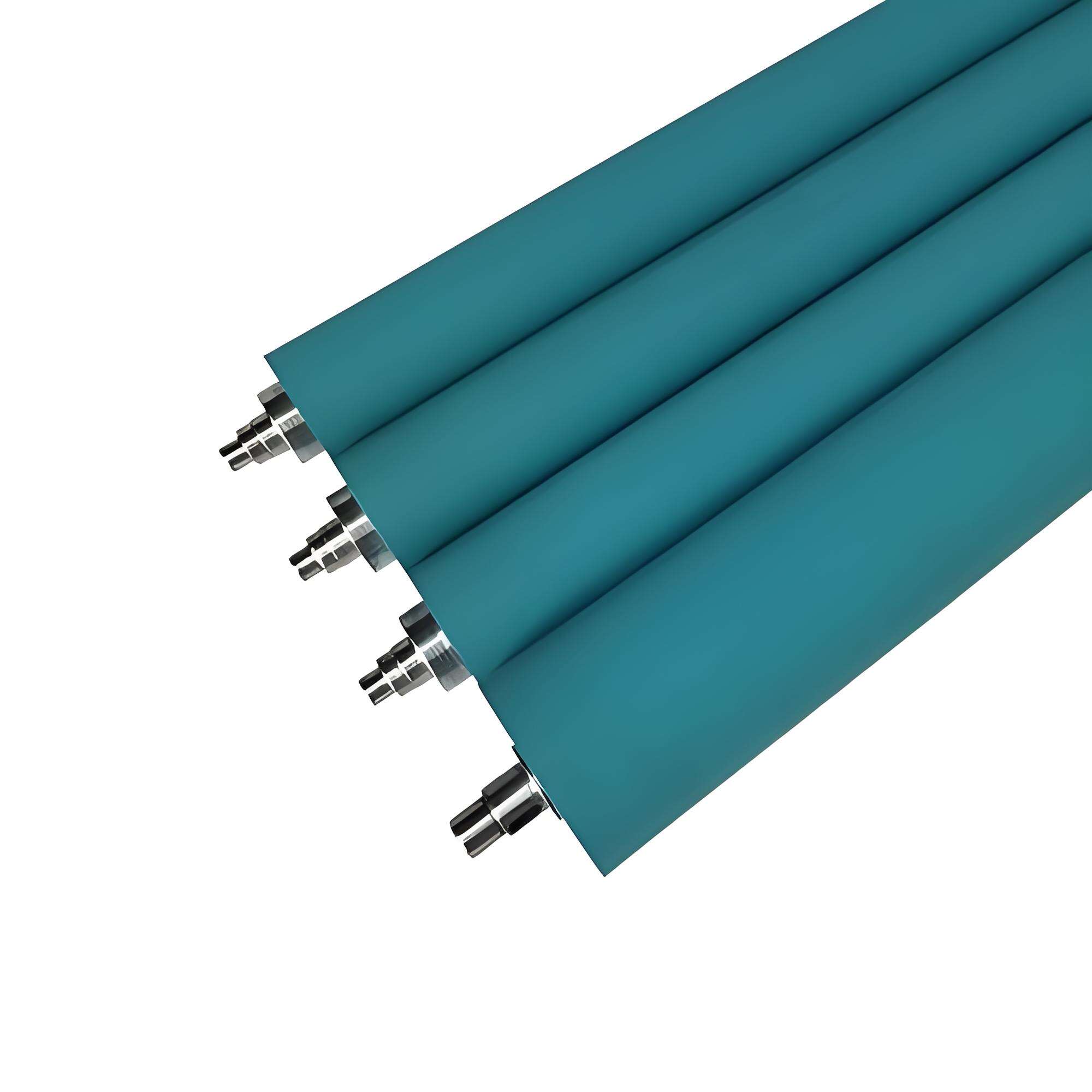

hard rubber roller

A hard rubber roller is a crucial industrial component designed for various material processing and manufacturing applications. These precision-engineered cylinders feature a durable hard rubber coating bonded to a metal core, offering exceptional wear resistance and dimensional stability. The surface hardness typically ranges from 65 to 95 Shore A, allowing for optimal performance in demanding environments. These rollers excel in applications requiring precise material handling, pressure application, and consistent surface contact. The hard rubber compound used in these rollers is specially formulated to resist chemicals, oils, and temperature variations while maintaining its physical properties. They are engineered to provide uniform pressure distribution, ensuring consistent processing results across the entire roller width. The metal core provides structural integrity and proper mounting capabilities, while the hard rubber exterior delivers the necessary friction and durability for various industrial processes. These rollers are commonly found in printing, paper processing, textile manufacturing, and converting industries, where they play a vital role in material transport, laminating, coating, and finishing operations. The design incorporates precision grinding of the rubber surface to achieve specific dimensional tolerances and surface characteristics, making them suitable for high-precision applications.