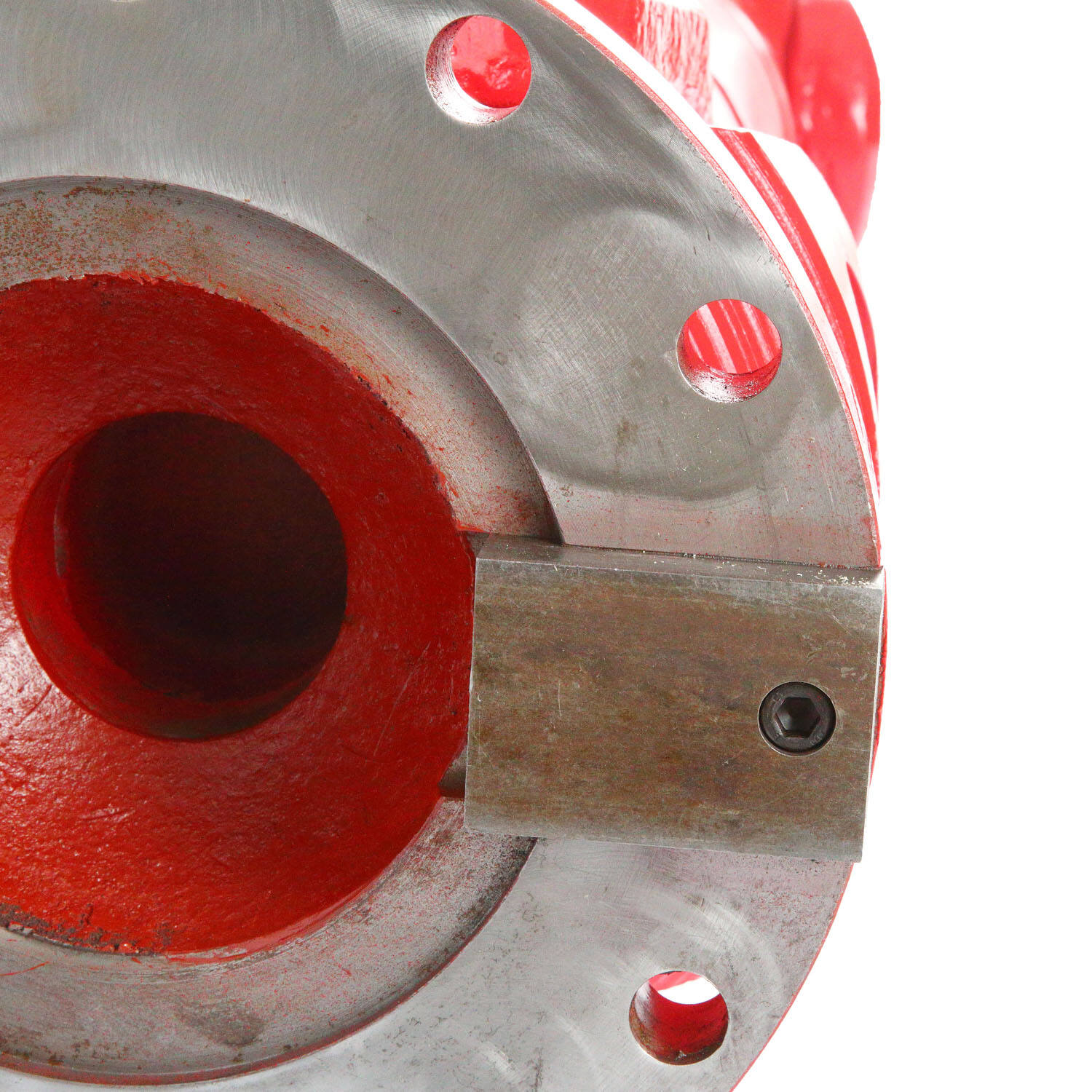

cardan axle

The cardan axle, also known as a drive shaft or propeller shaft, is a critical component in vehicle power transmission systems that enables the transfer of rotational power from the transmission to the differential. This sophisticated mechanical element consists of universal joints at both ends, allowing for smooth power transmission even when the shaft operates at varying angles. The design incorporates splined sections that accommodate changes in shaft length during vehicle suspension movement, ensuring consistent power delivery. Modern cardan axles feature precision engineering with high-grade materials like alloy steel and advanced bearing systems that enhance durability and performance. They are essential in vehicles with rear-wheel drive, four-wheel drive, and all-wheel drive configurations, where power must be transmitted along the vehicle's length. The axle's construction typically includes carefully balanced components to minimize vibration and ensure smooth operation at high rotational speeds. Industrial applications extend beyond automotive use to include manufacturing equipment, agricultural machinery, and marine propulsion systems, where reliable power transmission across distances or through changing angles is required.