فهم برج التبريد وصلات

التعريف والوظيفة الأساسية

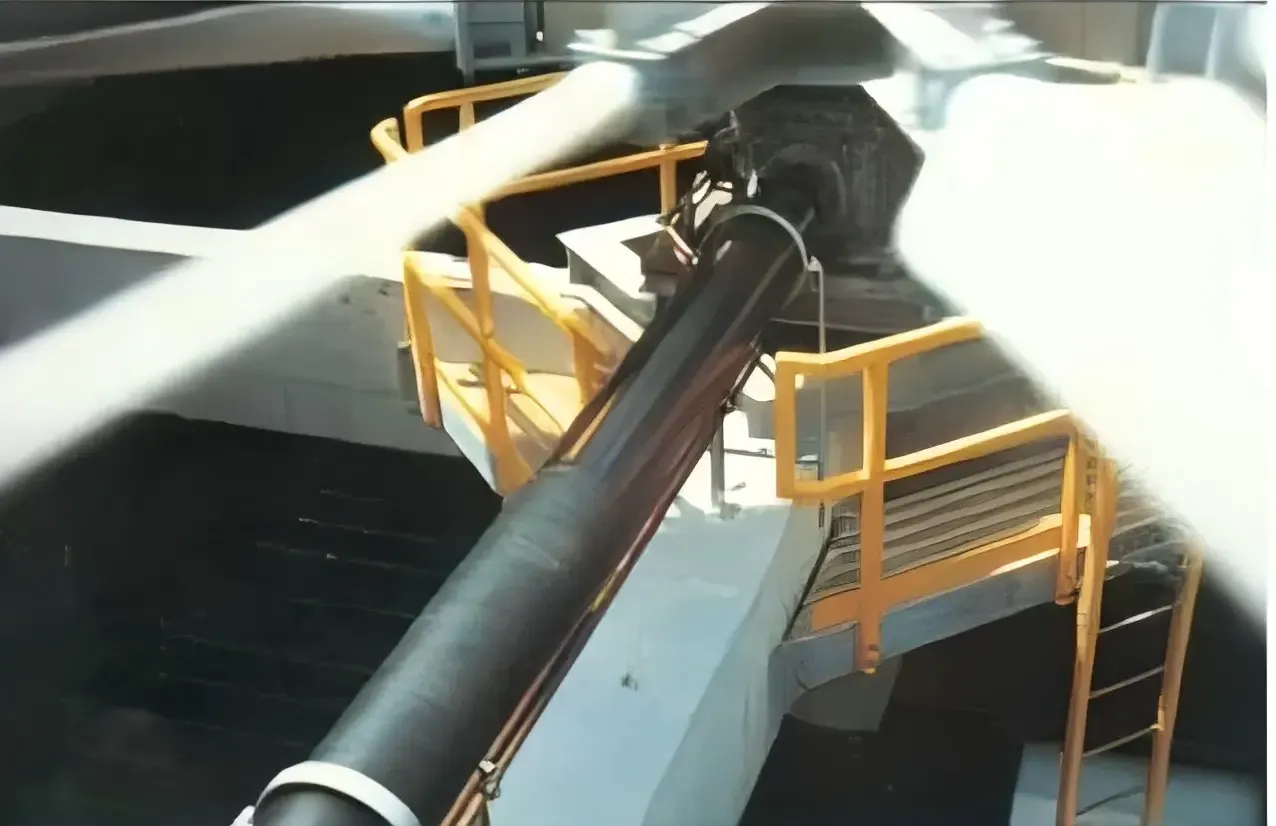

في أنظمة التبريد، تعمل المفاصل البرجية كروابط ميكانيكية أساسية تربط المحاور مع المراوح أو المضخات. ما تقوم به هذه المكونات بشكل أساسي هو نقل العزم عبر المحاور التي لا تكون محاذاتها مثالية، مما يحافظ على تشغيل النظام بسلاسة دون حدوث أعطال متكررة. في الواقع، تصنع المفاصل ذات الجودة العالية فرقاً كبيراً في الأداء العام لأنظمة التبريد لأنها تساعد على منع التآكل غير الضروري على أجزاء المعدات. كما يوجد عدة أنواع مختلفة منها – خيارات مرنة لحالات وجود بعض الحركة في النظام، وأنواع صلبة للتركيبات التي تكون فيها المحاذاة مستقرة. عند اختيار النوع المناسب لتركيب معين، يحتاج المهندسون إلى أخذ عوامل مثل مستويات الاهتزاز، مدى درجات الحرارة، ونقاط الوصول للصيانة بعين الاعتبار، نظراً لأن هذه العوامل هي التي تحدد ما إذا كان المفصل المرن أو الصلب هو الأنسب لهذا التطبيق المحدد.

الارتباط بكفاءة النظام الكلي

عندما تكون اقترانات أبراج التبريد محاذاة بشكل صحيح، فإنها تعزز بشكل كبير كفاءة النظام بأكمله من خلال تقليل هدر الطاقة. الاقترانات ذات الجودة العالية لا تساعد فقط في تشغيل الأنظمة بسلاسة، بل تقلل أيضًا من الاهتزازات وتجعل نظام التبريد ككل أكثر موثوقية بكثير. هذا الأمر مهم لأن ضعف أداء الأنظمة يُشعر الجميع بالتأثيرات السلبية. أظهرت أبحاث من عدة منشآت صناعية أن سوء محاذاة الاقتران يمكن أن يتسبب في تكاليف إضافية للطاقة بنسبة تصل إلى 10٪ في العمليات الكبيرة، وهي نسبة يحرص مديرو المصانع على تجنبها. يوصي معظم الخبراء بفحص هذه المكونات بانتظام على مدار عمرها الافتراضي. إن الاهتمام البسيط بهذه الأجزاء يسهم بشكل كبير في الحفاظ على مستويات الكفاءة المرتفعة، ويمنع الأعطال المكلفة في المستقبل، ولذلك يشدد معظم المصنّعين الموثوقين على أهمية الفحص الدوري كجزء من أي برنامج صيانة شامل.

تأثيرات كفاءة الطاقة لاقترانات عمود الدوران

تقليل خسائر نقل القوة

تلعب وصلات عمود الدفع دوراً أساسياً عندما يتعلق الأمر بتحقيق كفاءة أفضل في استخدام الطاقة في الأنظمة الصناعية. تربط هذه الوصلات الميكانيكية بين أجزاء مختلفة من الآلات وتنقل الطاقة بقليل من الاحتكاك من المصدر الذي يحرك النظام إلى المكان الذي تحتاج فيه إلى تلك الطاقة. ما يهم حقاً في هذا السياق هو جودة هذه الوصلات، لأن الوصلات ذات الجودة المنخفضة تؤدي إلى هدر كبير في الطاقة أثناء النقل. يلاحظ المصنعون الذين يستثمرون في مواد ذات جودة عالية لصنع وصلات عمود الدفع تحسناً ملحوظاً في كفاءة نقل الطاقة. تشير بعض الدراسات إلى أن التوفير يمكن أن يتراوح ما بين حوالي 5٪ حتى نحو 15٪، ويعتمد ذلك على نوع المعدات قيد المناقشة. إن تقليل الطاقة المهدورة يعني عمليات أكثر خضرة وفواتير أقل في نهاية الشهر، وهي أمور يقدّرها مديرو المصانع دائماً.

تقليل الاهتزاز وإنتاج الحرارة

تلعب تقليل الاهتزازات في الأنظمة الميكانيكية دوراً كبيراً، لأنها تؤثر على عمر المعدات الطويل وعلى فواتير الصيانة التي تظهر لاحقاً. تعمل المحابس عالية الجودة كوسائد هوائية للمعدات، حيث تمتص الصدمات والاهتزازات المزعجة التي تؤدي مع الوقت إلى تآكل المكونات. عندما يتم امتصاص الاهتزازات بشكل صحيح، يقل تراكم الحرارة الناتج عن الاحتكاك داخل مكونات النظام. يتفق خبراء الصناعة عموماً على أن تقليل الاهتزازات يمكن أن يطيل عمر الماكينة بنسبة تصل إلى 30٪ تقريباً، ويعتمد ذلك على الظروف المحيطة. ولهذا يصبح استثمار المال في محابس جيدة النوع مفيداً على المدى الطويل. كما أن التخلص من الاهتزازات غير المرغوب فيها يساعد في توفير الطاقة، لأن الماكينات لا تحتاج إلى بذل جهد كبير ضد اهتزازاتها الداخلية. بالإضافة إلى ذلك، عندما تكون الاهتزازات تحت السيطرة، تنخفض حالات تلف القطع بشكل متكرر، مما يعني تقليل عدد مرات الاتصال لإصلاح الأعطال، وبالتالي خفض تكاليف الصيانة الإجمالية لمشغلي المصانع.

فوائد الصيانة والتشغيل

منع توقف تشغيل المعدات

إن الحفاظ على توصيلات البرج المبرد في حالة جيدة من الصيانة يساعد حقًا في تجنب تلك الأعطال المفاجئة التي تؤدي إلى تكاليف باهظة بسبب توقف العمليات. عندما تلتزم المصانع بجداول صيانة منتظمة لهذه المكونات، فإنها تلاحظ موثوقية أفضل بكثير في النظام وحدوث اضطرابات تشغيلية أقل يوميًا. تشير الأبحاث إلى أن العناية المناسبة لتوصيلات البرج المبرد تقلل من توقف المعدات بنسبة تقارب 20 بالمئة، مما يعزز الإنتاجية بشكل عام. وبعيدًا عن الحفاظ على سير العمليات بسلاسة، فإن هذا النوع من الصيانة يوفّر في الواقع الطاقة أيضًا. حيث لا تضطر الأنظمة إلى الدخول في دورات متكررة من الإيقاف والإعادة، بل تعمل معظم الوقت بمستوى أداء مثالي بدلًا من العمل بجهد في ظل تشغيل غير فعال.

تمديد عمر النظام

عند اختيار اقترانات أبراج التبريد بعناية والحفاظ على حالتها الجيدة، فإنها تُحدث فرقًا كبيرًا في مدة عمر النظام الكامل للتبريد. تتحمل الاقترانات ذات الجودة العالية جزءًا كبيرًا من الضغط الواقع على مكونات الدفع والأجزاء الأخرى المتصلة، مما يعني حدوث أعطال أقل وتكاليف صيانة منخفضة على مر السنين. تشير البيانات الصناعية إلى أن الصيانة الدورية لهذه الاقترانات يمكن أن تمدد عمر النظام عدة سنوات وفقًا لتقارير المصنعين. بالنسبة لمديري المصانع الذين يركزون على النتائج المالية، فإن هذا الأمر مهم للغاية لأنه يحمي الاستثمارات الرأسمالية ويضمن استمرار العمليات دون انقطاع يومًا بعد يوم. كما أن الاهتمام الجيد بجودة الاقتران يُحقق عوائد من حيث موثوقية النظام أيضًا، مما يساعد المنشآت على الحفاظ على الأداء المتسق ومنع الإغلاقات المفاجئة التي تُعيق جداول الإنتاج.

اختيار اقترانات أبراج التبريد ذات الجودة العالية

معايير التصنيع الرئيسية

يعني اختيار أنابيب التبريد الصحيحة الانتباه إلى معايير التصنيع مثل شهادات ISO وANSI، وهي نقطة يغفل عنها الكثير من المحترفين لكن لا ينبغي تجاهلها أبدًا. ترمز هذه المعايير فعليًا إلى جودة المنتجات التي تمثلها. يجب أن تفي الأنابيب المعتمدة متطلبات صارمة فيما يتعلق باختيار المواد، وتحقيق الأبعاد بدقة، والخضوع لاختبارات متنوعة قبل مغادرتها المصنع، وهي عوامل تؤثر مباشرة على كفاءتها على المدى الطويل. كما أن المعايير الصناعية ليست مجرد أوراق رسمية، فهي توفر إرشادات عملية حول أفضل ما يمكن استخدامه في ظروف مختلفة، وتساعد المهندسين على العثور على أنابيب تتناسب مع متطلبات نظامهم المحدد. وتمتد أهمية الشهادات المعتمدة لتحسين الأداء الكلي للنظام، إذ أن الأجزاء المعتمدة تكون أقل عرضة للاعطال أثناء التشغيل.

اعتبارات توافق المواد

إن اختيار المواد يؤثر حقاً في أداء اقترانات أبراج التبريد واستمراريتها على المدى الطويل. توجد في السوق مواد مثل الفولاذ المقاوم للصدأ والنحاس وأنواع مختلفة من المواد المركبة لهذه التطبيقات. عند اختيار المواد، من المهم جداً مراعاة طبيعة البيئة التي ستعمل فيها. يمكن أن تؤثر درجات الحرارة القصوى والمواد الكيميائية الموجودة في المنطقة على بعض المواد إذا لم تتم مطابقتها بشكل صحيح. يجب أن تكون الاقترانات متوافقة جيداً مع باقي المعدات المثبتة في النظام أيضاً. وإلا فقد تظهر لاحقاً مشاكل في عدم أداء الاقترانات بشكل متوقع أو حتى التسبب في مشاكل في أجزاء أخرى من تركيب أبراج التبريد. عادةً ما تحقق الشركات التي تأخذ كل هذه العوامل بعين الاعتبار عند اختيار اقترانات عمود الدفع نتائج أفضل على المدى الطويل من حيث الأداء المالي والتشغيلي.

الأسئلة الشائعة

ماذا عن اتصالات أبراج التبريد؟

هي أجهزة ميكانيكية تربط محور القوة بشاحن التبريد أو مضخة أنظمة التبريد، وتقوم بنقل العزم وتحمل انحراف المحاور.

كيف تؤثر اتصالات أبراج التبريد على كفاءة الطاقة؟

تُحسّن مقايس أبراج التبريد من كفاءة الطاقة عن طريق تقليل خسائر الطاقة، وتقليل الاهتزاز، وزيادة موثوقية النظام، مما يساهم في أداء النظام العام.

لماذا تعتبر الصيانة الدورية لأبراج التبريد مهمة؟

الصيانة الدورية ضرورية لمنع الفشل المفاجئ، وتقليل وقت التوقف، وزيادة عمر النظام، مما يعزز الإنتاجية وكفاءة الطاقة.

ما الذي يجب مراعاته عند اختيار مقايس أبراج التبريد؟

تشمل العوامل الأساسية التي يجب أخذها بعين الاعتبار معايير التصنيع مثل شهادات الجودة ISO أو ANSI، والتوافق مع المواد لضمان المتانة ومكافحة التآكل.