Understanding Cooling Tower Couplings

Definition and Core Function

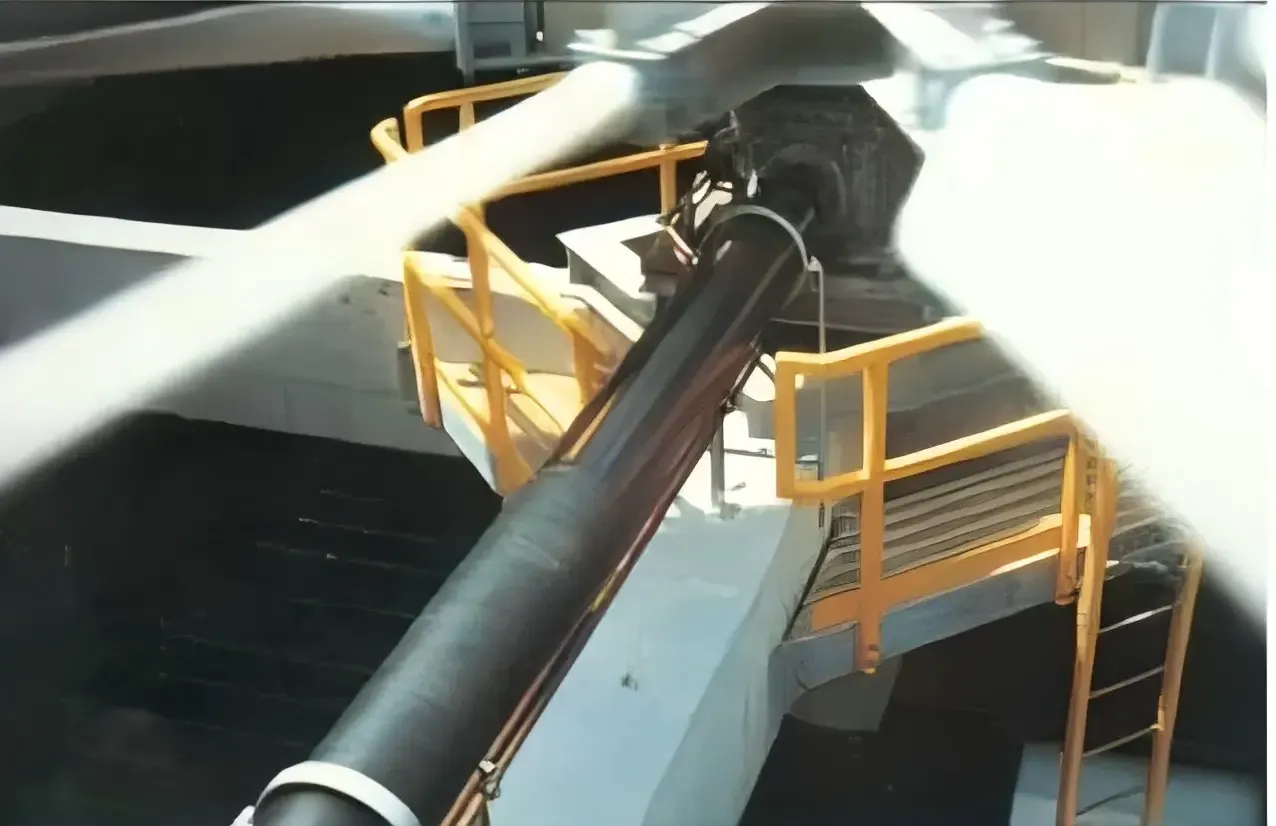

In cooling systems, tower couplings serve as essential mechanical links connecting drive shafts to fans or pumps. What these components do basically is transfer torque across shafts that aren't perfectly aligned, which keeps everything running smoothly without constant breakdowns. Good quality couplings actually make a big difference in how well cooling systems perform overall because they help prevent unnecessary wear on equipment parts. There are several different kinds available too – flexible options for when there might be some movement in the system, and rigid ones for setups where alignment stays consistent. When selecting the right type for a particular installation, engineers need to consider factors like vibration levels, temperature ranges, and maintenance access points since these will determine whether a flexible or rigid coupling works best for that specific application.

Connection to Overall System Efficiency

When cooling tower couplings are properly aligned, they really boost how well the whole system works by cutting down on wasted energy. Good quality couplings do more than just keep things running smoothly they actually cut vibrations and make the entire cooling setup much more dependable. This matters because when systems aren't performing at their best, everyone feels it. Research from several industrial facilities shows that poor coupling alignment can cause around 10% extra energy costs in big operations, something plant managers definitely want to avoid. Most experts recommend checking these components regularly throughout their service life. A little attention goes a long way toward keeping efficiency levels high while avoiding expensive breakdowns down the road, which is why most reputable manufacturers stress routine inspection as part of any comprehensive maintenance program.

Energy Efficiency Impacts of Drive Shaft Couplings

Reducing Power Transmission Losses

Drive shaft couplings play a crucial role when it comes to getting better energy efficiency out of industrial systems. These mechanical links connect different parts of machinery and transfer power with little friction from whatever drives the system to wherever that power needs to go. What really matters here is the quality of these couplings because poor ones will waste a lot of energy during transmission. Manufacturers who invest in good quality materials for their drive shaft couplings see noticeable improvements in power transfer efficiency. Some studies suggest savings range anywhere from about 5% up to around 15%, though this varies depending on what kind of equipment we're talking about. Less wasted energy means both greener operations and lower bills at month end, something plant managers always appreciate.

Minimizing Vibration and Heat Generation

Reducing vibration in mechanical systems matters a lot because it affects how long equipment lasts and what kind of maintenance bills come in. Good quality couplings serve as shock absorbers for machinery, taking the edge off those annoying vibrations that wear things down over time. When vibrations get absorbed properly, there's less heat buildup from all that friction inside the system components. Industry folks generally agree that cutting down on vibrations can extend machine life somewhere around 30% give or take depending on conditions. That makes spending money on decent couplings worthwhile in the long run. Getting rid of unwanted vibrations also helps save energy since machines don't have to work as hard against themselves. Plus, when vibrations are under control, parts don't break down so often, which means fewer repair calls and lower overall maintenance expenses for plant operators.

Maintenance and Operational Benefits

Preventing Equipment Downtime

Keeping those cooling tower couplings well maintained really helps avoid those surprise breakdowns that end up costing a fortune in downtime. When plants stick to regular maintenance schedules for these components, they see much better system reliability and fewer operational hiccups day to day. Research indicates proper care of cooling tower couplings cuts down on equipment downtime somewhere around 20 percent or so, which naturally boosts productivity across the board. Beyond just keeping things running smoothly, this kind of maintenance actually saves energy too. The systems don't get stuck in stop-start cycles as often, and everything runs at peak performance most of the time instead of struggling through inefficient operation.

Extending System Lifespan

When cooling tower couplings are chosen carefully and kept in good condition, they really do make a big difference in how long the whole cooling system lasts. Good quality couplings take the strain off the drive components and other parts connected to them, which means fewer breakdowns and less money spent on repairs over time. Industry data shows that regular maintenance of these couplings can actually extend system life by several years according to manufacturer reports. For plant managers looking at their bottom line, this matters a lot since it protects capital investments while keeping operations running smoothly day after day. The right attention to coupling quality pays dividends in terms of system reliability too, helping facilities maintain consistent performance without unexpected shutdowns disrupting production schedules.

Selecting Quality Cooling Tower Couplings

Key Manufacturing Standards

Choosing the right cooling tower couplings means looking at manufacturing standards like ISO and ANSI certifications, something many professionals overlook but should never skip. These standards actually mean real things for the product quality they represent. Certified couplings must meet strict requirements when it comes to picking materials, getting dimensions just right, and passing various tests before leaving the factory all factors that directly impact how well they work over time. Industry standards aren't just paperwork either they provide practical guidance on what works best in different situations, helping engineers find couplings that fit their particular system requirements. Beyond just making manufacturers look good on paper, proper certification translates to better system performance because certified parts simply don't fail as often during operation.

Material Compatibility Considerations

What materials we pick really affects how well cooling tower couplings perform and last over time. Stainless steel, brass, and various composite materials are all on the market for this application. When picking materials, it matters a lot what kind of environment they'll be working in. Temperature extremes and chemicals present in the area can eat away at certain materials if not matched properly. The couplings need to work well with whatever else is already installed in the system too. Otherwise, there might be problems down the road with them not functioning as intended or even causing issues elsewhere in the cooling tower setup. Companies that take all these things into account when choosing drive shaft couplings tend to see better results in the long run both operationally and financially speaking.

FAQ

What are cooling tower couplings?

Cooling tower couplings are mechanical devices that connect the drive shaft to the fan or pump in cooling systems, transmitting torque and accommodating shaft misalignments.

How do cooling tower couplings impact energy efficiency?

Cooling tower couplings enhance energy efficiency by minimizing energy losses, reducing vibration, and increasing system reliability, contributing to overall system performance.

Why is regular maintenance of cooling tower couplings important?

Regular maintenance is crucial for preventing unexpected failures, reducing downtime, and increasing system lifespan, thereby enhancing productivity and energy efficiency.

What should be considered when selecting cooling tower couplings?

Key considerations include manufacturing standards like ISO or ANSI certifications for quality, and material compatibility for durability and corrosion resistance.