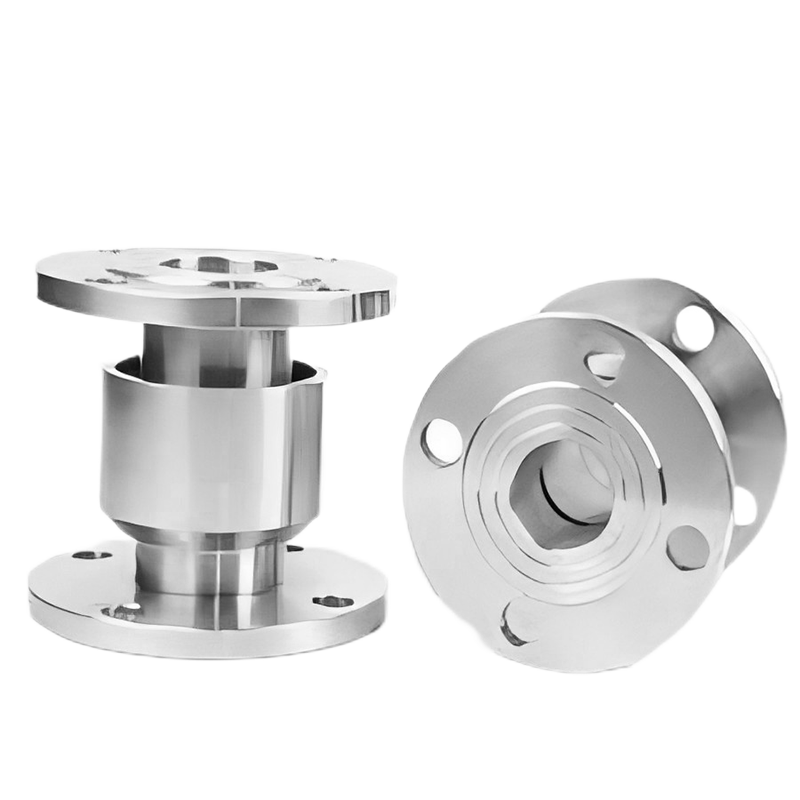

automotive universal joint

The automotive universal joint, commonly known as a U-joint, is a crucial mechanical component that enables power transmission between two shafts positioned at different angles. This essential part allows for flexible movement while maintaining consistent rotational speed and torque transfer throughout the driveline system. The joint consists of a cross-shaped central component with four protruding trunnions, each fitted with needle bearings and held in place by caps within a yoke assembly. This ingenious design allows for articulation in multiple directions, making it indispensable in vehicle drivetrains. Universal joints are particularly vital in vehicles with rear-wheel or four-wheel drive configurations, where they facilitate the connection between the transmission and differential while accommodating changes in suspension movement and driveshaft angle. Modern automotive universal joints incorporate advanced materials and precision engineering to ensure durability, smooth operation, and minimal maintenance requirements. These components are designed to withstand severe operating conditions, including high torque loads, varying angles, and exposure to environmental elements. The universal joint's ability to maintain proper power transfer while compensating for misalignment makes it an integral part of vehicle performance and reliability.