Understanding the Essential Role of Couplings in Industrial Cooling Systems

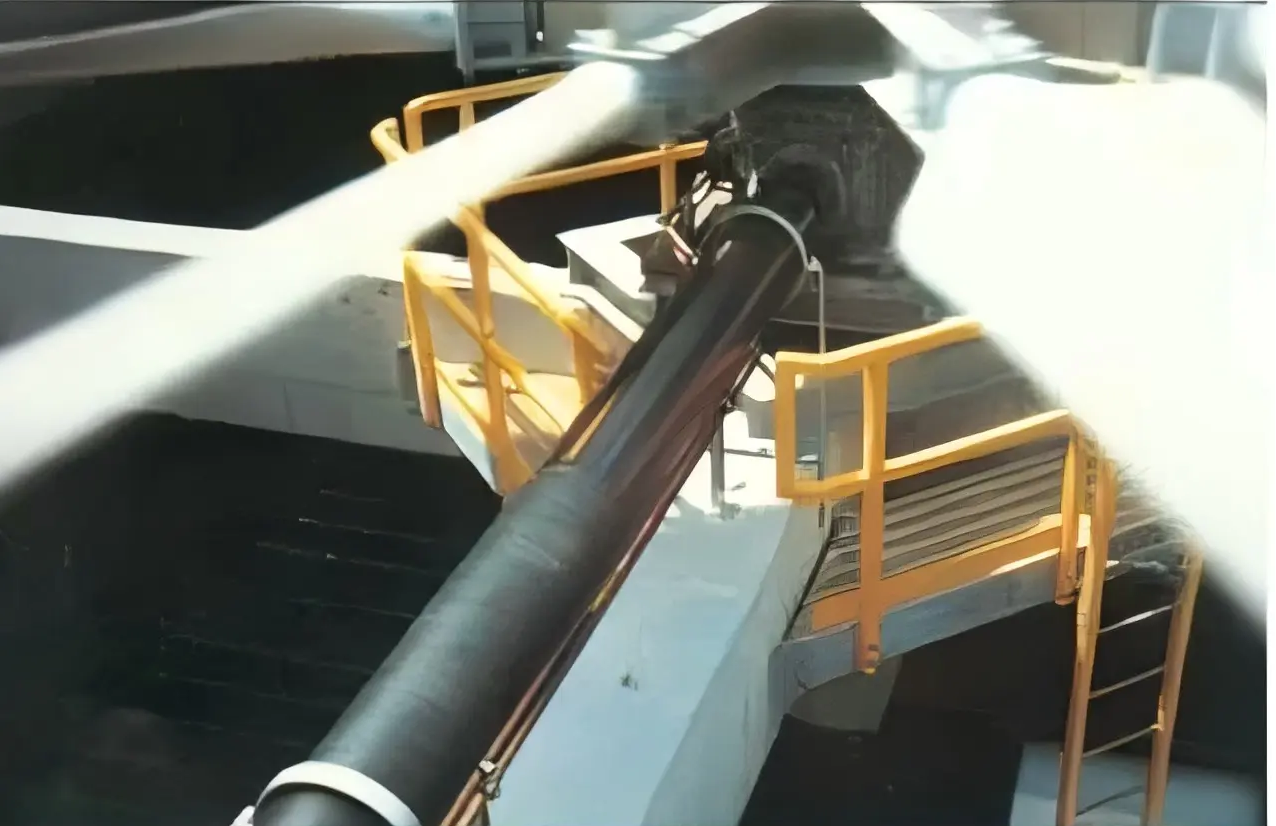

Industrial cooling towers represent the backbone of many manufacturing and processing facilities, and at the heart of these critical systems lie cooling tower couplings. These precision-engineered components serve as vital connectors between driving and driven equipment, ensuring smooth power transmission while accommodating inevitable misalignment and vibration. Their significance extends far beyond simple mechanical connection – they directly impact system efficiency, maintenance requirements, and overall operational reliability.

The industrial landscape continues to evolve, with increasing demands for higher performance and reliability from cooling tower systems. In this context, cooling tower couplings have emerged as crucial components that can either enhance or compromise entire system operations. Whether in petrochemical plants, power generation facilities, or HVAC systems for large commercial buildings, the selection and maintenance of these couplings can make the difference between optimal performance and costly downtime.

Design Principles and Engineering Considerations

Material Selection and Durability Requirements

The harsh operating environment of cooling towers demands exceptional material selection for couplings. These components must withstand constant exposure to moisture, chemicals, and varying temperature conditions. High-grade stainless steel and advanced composite materials are commonly employed in modern cooling tower couplings, offering superior corrosion resistance and longevity.

Engineers must carefully consider factors such as torque requirements, speed variations, and environmental conditions when selecting coupling materials. The chosen materials must maintain their structural integrity while providing the necessary flexibility to accommodate operational demands. This balance between strength and flexibility is crucial for long-term reliability.

Precision Engineering and Tolerance Specifications

Modern cooling tower couplings are manufactured to exacting tolerances to ensure optimal performance. The precision of these components directly affects vibration levels, power transmission efficiency, and overall system reliability. Advanced manufacturing techniques, including CNC machining and quality control processes, ensure that each coupling meets stringent specifications.

Proper sizing and specification of cooling tower couplings require detailed analysis of system requirements, including operational speeds, torque transmission needs, and anticipated misalignment conditions. Engineers must account for both steady-state operation and transient conditions that may occur during startup or unusual operating scenarios.

Operational Benefits and Performance Advantages

Energy Efficiency and Power Transmission

Well-designed cooling tower couplings play a crucial role in maintaining system efficiency. By effectively transmitting power while minimizing losses due to misalignment or vibration, these components help optimize energy consumption. The right coupling design can reduce power losses by up to 15% compared to poorly specified alternatives.

Modern coupling designs incorporate features that enhance power transmission efficiency while providing necessary flexibility. This balance results in reduced energy consumption and lower operational costs over the system's lifetime. The initial investment in high-quality cooling tower couplings typically pays for itself through improved efficiency and reduced maintenance requirements.

Maintenance Requirements and System Longevity

Quality cooling tower couplings significantly impact maintenance schedules and system lifespan. Properly specified and installed couplings require minimal maintenance, often limiting necessary attention to routine inspections and occasional lubrication where applicable. This reduced maintenance burden translates to lower operational costs and improved system availability.

The longevity of cooling tower systems is directly influenced by coupling performance. Superior couplings protect connected equipment by absorbing shock loads and dampening vibration, thereby extending the life of motors, gearboxes, and other critical components. This protective function results in reduced replacement costs and fewer unexpected failures.

Installation and Maintenance Best Practices

Proper Installation Procedures

The success of cooling tower couplings begins with proper installation. Technicians must follow precise alignment procedures and torque specifications to ensure optimal performance. Modern laser alignment tools and detailed installation guides help achieve the necessary precision for proper coupling operation.

Installation considerations include careful handling of components, proper cleaning of mating surfaces, and accurate torque application to fasteners. These steps, while seemingly basic, are crucial for achieving the expected performance and reliability from cooling tower couplings.

Monitoring and Preventive Maintenance

Regular monitoring of cooling tower couplings helps identify potential issues before they lead to system failures. This includes visual inspections for signs of wear, vibration analysis, and periodic alignment checks. Modern monitoring systems can provide real-time data on coupling performance, enabling predictive maintenance approaches.

Maintenance programs should include regular assessment of coupling condition, including checks for wear, corrosion, and proper alignment. Documentation of inspection results and maintenance activities helps track component performance over time and aids in predicting replacement needs.

Future Trends and Technological Advancements

Smart Coupling Technologies

The future of cooling tower couplings includes integration with smart monitoring systems. Embedded sensors and connectivity features allow real-time performance monitoring and early detection of potential issues. These advanced technologies enable predictive maintenance strategies and improved system reliability.

Developments in materials science and manufacturing techniques continue to enhance coupling capabilities. New composite materials and advanced coating technologies offer improved performance characteristics while reducing weight and maintenance requirements.

Sustainability and Environmental Considerations

Modern cooling tower couplings are being designed with increased focus on environmental sustainability. This includes the use of eco-friendly materials, improved energy efficiency, and designs that minimize the need for lubricants or other potentially harmful substances.

Manufacturers are developing innovative solutions that reduce environmental impact while maintaining or improving performance characteristics. These advances align with global initiatives for sustainable industrial operations and reduced environmental footprint.

Frequently Asked Questions

How often should cooling tower couplings be inspected?

Regular inspections should be conducted at least quarterly, with more frequent checks in demanding applications or harsh environments. Visual inspections can be performed monthly, while detailed alignment checks and vibration analysis may be scheduled quarterly or semi-annually based on operating conditions.

What are the signs of coupling failure?

Common indicators include unusual vibration, noise, excessive heat generation, visible wear or damage, and changes in system performance. Early detection through regular monitoring can prevent catastrophic failures and minimize downtime.

What factors should be considered when selecting cooling tower couplings?

Key considerations include system power requirements, operating speeds, expected misalignment conditions, environmental factors, maintenance accessibility, and life-cycle costs. Working with experienced engineers and manufacturers ensures proper selection for specific applications.