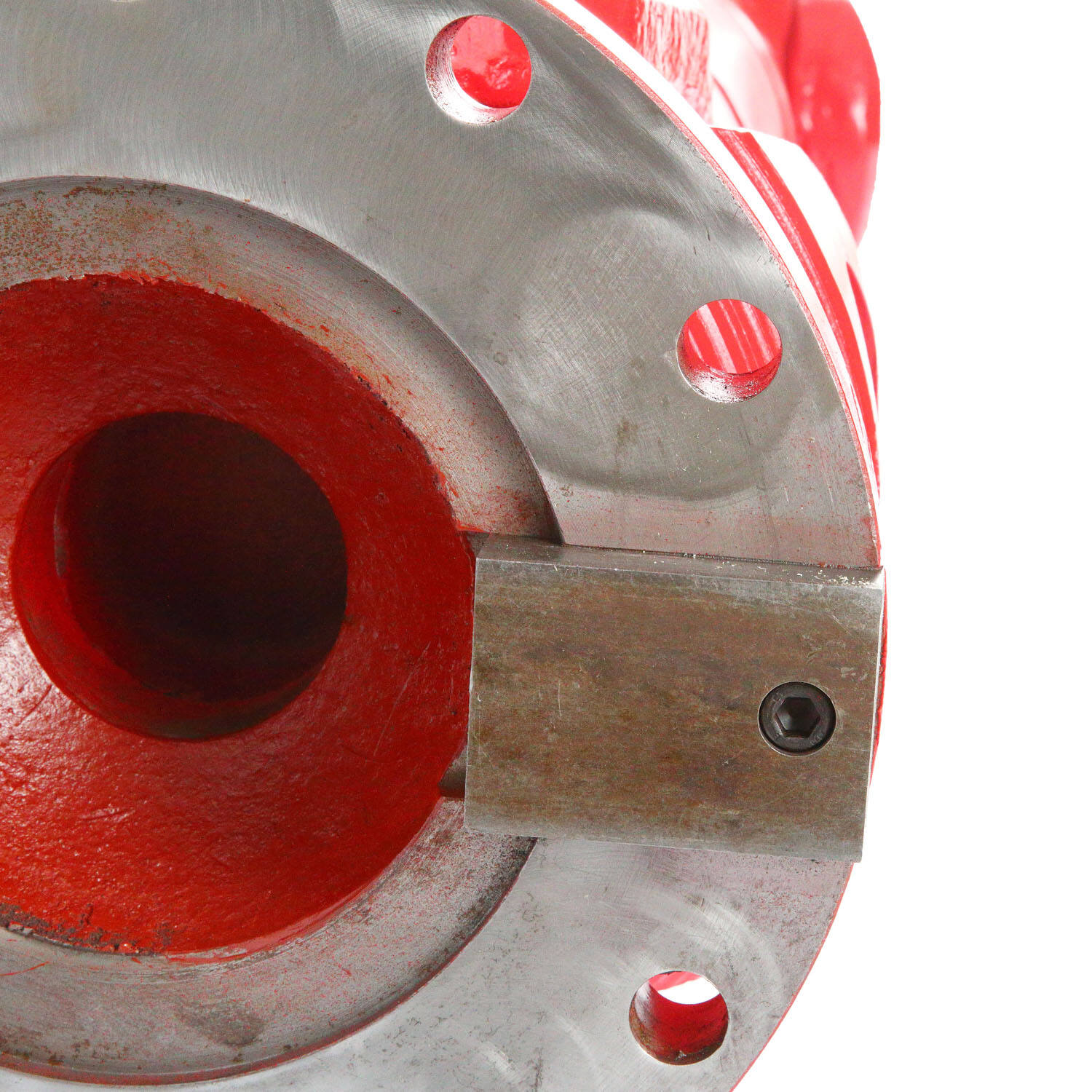

double cardan propshaft

The double cardan propshaft represents a sophisticated advancement in automotive drivetrain technology, designed to ensure smooth power transmission across varying angles between the engine and driven wheels. This specialized component consists of two universal joints connected by an intermediate shaft, allowing for enhanced articulation and reduced vibration compared to single-joint designs. The system works by compensating for the inherent speed fluctuations that occur in standard universal joints, maintaining constant velocity output even at extreme operating angles. In automotive applications, the double cardan propshaft proves particularly valuable in vehicles with significant suspension travel or where substantial angular displacement between the transmission and differential is necessary. The design incorporates precision-engineered bearing assemblies and carefully balanced components to minimize wear while maximizing durability. Modern double cardan propshafts often feature advanced materials such as high-strength steel alloys and specialized lubricants to enhance performance and longevity. This technology finds extensive use in four-wheel-drive vehicles, heavy machinery, and industrial applications where reliable power transmission across varying angles is crucial. The system's ability to maintain smooth operation while accommodating significant angular misalignment makes it an essential component in modern vehicle design.